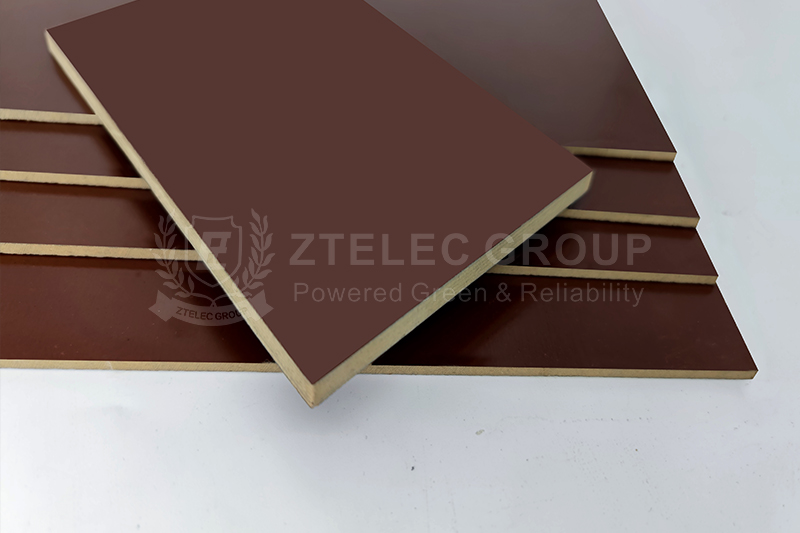

In the field of insulation materials, phenolic paper sheet has become an ideal choice for many industries due to its unique performance shaped by phenolic resin as the core raw material. It has shown irreplaceable advantages in multiple application scenarios. The following will explore in depth the applicable fields of phenolic paper sheet and the principles behind it.

Phenolic paper sheet occupies an important position in the manufacture of low-voltage electrical insulation parts and is often used in knife switch bases, distribution box wiring baffles and other components.

Phenolic paper sheet has excellent electrical insulation performance and has extremely high volume resistivity and breakdown voltage. This enables it to effectively isolate current, prevent leakage risks, and build a reliable protective barrier for the safe and stable operation of low-voltage electrical equipment.

Its mechanical strength is just right and can withstand the mechanical stress and impact generated during the operation of low-voltage electrical equipment. Under frequent opening and closing or vibration conditions, phenolic paper sheet can still maintain structural integrity to ensure the normal operation of the equipment.

Compared with other high-performance insulating materials, phenolic paper sheet has a low production cost and is suitable for large-scale industrial production. This feature effectively reduces the manufacturing cost of low-voltage electrical equipment, while ensuring performance and improving the market competitiveness of the product.

In the field of electronics industry, phenolic paper sheet also plays an important role and is widely used in insulating gaskets, partitions and other parts of printed circuit boards (PCBs).

Phenolic paper sheet has good processing adaptability and is easy to cut, drill and other processing operations. It can be accurately processed into various shapes and sizes. This feature perfectly meets the electronics industry’s demand for diversified and precise insulating parts.

In a complex electronic circuit environment, phenolic paper sheet always maintains stable electrical performance, ensures accurate transmission of electronic signals, and provides solid protection for the normal operation of electronic equipment.

During the production and use process, phenolic paper sheet does not produce harmful substances, meets the increasingly stringent environmental protection requirements of the electronics industry, and conforms to the trend of green development in the industry.

Phenolic paper sheet also performs well in the insulation structure of electrical equipment such as transformers and motors, and is often used as a key insulation structure component.

Phenolic paper sheet has good heat resistance and can maintain stable performance within a certain temperature range, meeting the insulation requirements of equipment such as transformers and motors in high-temperature operating environments, and effectively avoiding insulation failure caused by temperature rise.

It has strong chemical corrosion resistance and can resist corrosion from a variety of chemical substances. Even in harsh environments containing corrosive gases or liquids, phenolic paper sheet can still maintain stable insulation performance and ensure long-term reliable operation of electrical equipment.

The mechanical strength of phenolic paper sheet can meet the strength requirements of transformers and motors for insulation structure components. During the operation of the equipment, it withstands internal electromagnetic forces and mechanical vibrations to maintain the integrity and stability of the insulation structure.

The extremely high volume resistivity and breakdown voltage make it an excellent choice for electrical insulation, providing safe and reliable insulation protection for various electrical equipment.

The moderate mechanical strength makes it suitable for a variety of application scenarios, which can not only meet the strength requirements, but also take into account cost control, and achieve a balance between performance and economy.

Within a certain temperature range, phenolic paper sheet has stable performance and can adapt to the insulation work of electrical equipment in high temperature environments, which broadens its application range.

The strong chemical corrosion resistance enables it to ensure the long-term stable operation of electrical equipment in harsh chemical environments and improve the service life of equipment.

The easy processing characteristics can meet the diverse needs of users, realize the rapid customization of insulation parts, and improve production efficiency.

The environmental protection characteristics of the production and use process make it meet the requirements of modern industrial green development and help enterprises achieve sustainable development goals.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……