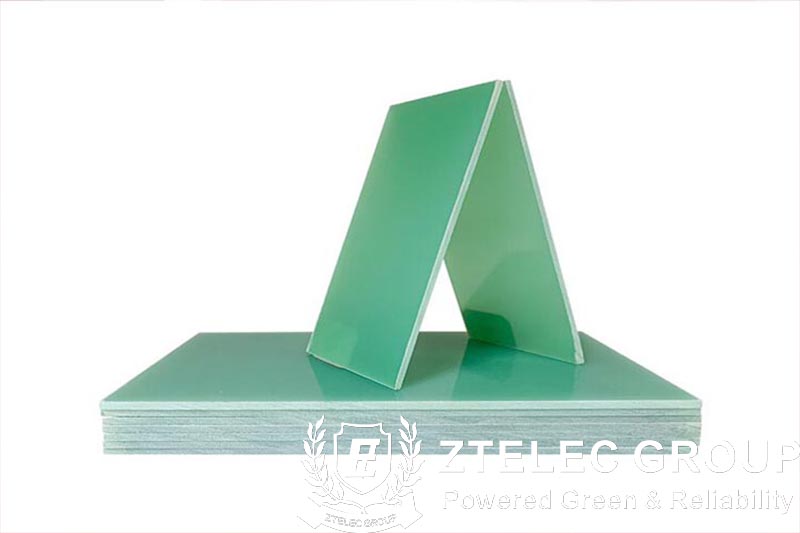

FR4 and FR5 insulation materials are both epoxy glass fiber cloth laminates, which are made of alkali-free glass fiber cloth impregnated with epoxy resin, and added with flame retardants, adhesives and other additives, and processed by hot pressing. This manufacturing process ensures that they have a hard plate structure, thus providing good mechanical strength and insulation performance.

FR4: It has high thermal stability and can maintain its performance stability under certain high temperature environment. However, its heat resistance is relatively limited, usually around 150°C.

FR5: Although it can also be used in high temperature environments, its thermal stability is slightly inferior to FR4. However, FR5’s heat resistance is significantly better than FR4. The maximum operating temperature of FR5 can reach 160°C, and its heat resistance is about twice that of ordinary FR4. This makes FR5 more widely used in high temperature environments, especially in situations where higher heat resistance is required.

FR4: The tensile strength is relatively low and it is easily affected by mechanical and thermal stress. This limits the use of FR4 in certain applications that require high strength and wear resistance.

FR5: It has high tensile strength and can withstand greater mechanical and thermal stress. This makes FR5 perform well in situations where it needs to withstand large loads and wear.

FR4: It has a certain water absorption rate. Although it is usually low, its performance may be affected to a certain extent when it is exposed to a humid environment for a long time.

FR5: The water absorption rate is almost zero, and the water absorption rate after immersion in water for 24 hours is also extremely low (such as 0.09%). This feature makes FR5 more stable in a humid environment and less likely to degrade due to water absorption.

FR4: It has a relatively high coefficient of thermal expansion, which may affect the dimensional stability of FR4 in environments with high temperatures or large temperature changes.

FR5: It has a smaller coefficient of thermal expansion (smaller Z-CTE), which allows FR5 to maintain better dimensional stability in environments with high temperatures or temperature changes. This feature is particularly important for occasions such as high-layer boards that require precise dimensional control.

FR4: It has stable electrical insulation performance and can provide reliable electrical insulation to ensure the safe operation of electronic equipment.

FR5: It also has excellent electrical performance and can meet the requirements of various electronic equipment for insulation materials. FR5 also performs well in the insulation partitions, insulation pads, transformer insulation parts, motor insulation parts, etc. of electrical equipment.

Electronic field: FR4 is commonly used in FPC reinforcement board, tin furnace high temperature resistant board, carbon diaphragm, precision planetary wheel, PCB test frame and other high-performance electronic insulation products.

Electrical field: FR4 is used for insulation partitions and insulation pads of electrical equipment.

Architectural field: FR4 is used as a soft package base and matched with fabrics, leather and other materials to make beautiful wall and ceiling decorations.

Electronic field: Due to its higher heat resistance and smaller thermal expansion coefficient, FR5 is more widely used in high-performance electronic insulation products, such as computer electronic equipment, electrical panels, circuit board fixtures, etc.

Mechanical field: FR5 is used to make mechanical parts, bearings, gaskets, gears, washers, etc.

Other fields: FR5 is used for converters, transformers, wear strips, etc. that need to withstand high temperatures and mechanical stress.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……