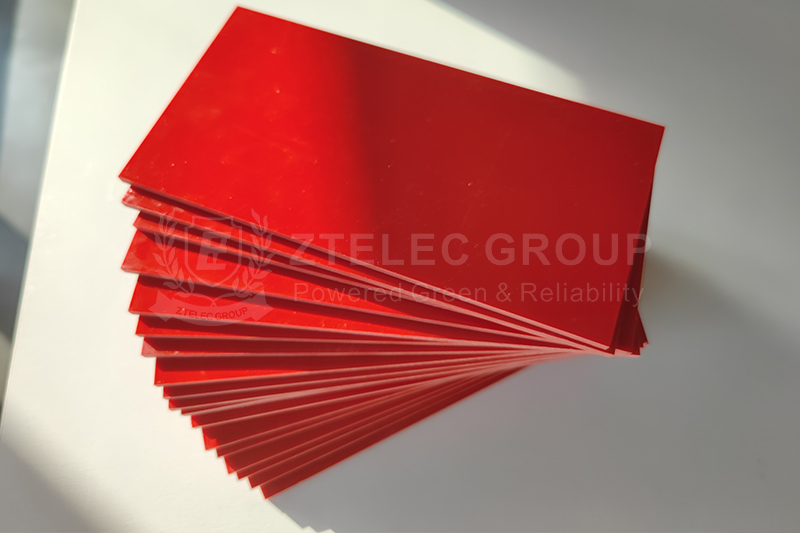

Bakelite sheet is a phenolic laminated paperboard, which is made by hot pressing bleached wood pulp paper after being impregnated with phenolic resin. Its thickness ranges from 3 to 50 mm, and its regular sizes are 1030×2030, 1040×2080, 1220×2440. Common colors are reddish orange or black. Bakelite sheet is non-absorbent, non-conductive, high temperature resistant, and high in strength. It is widely used in electrical products and industrial fields.

Excellent electrical insulation performance: Bakelite sheet has extremely high resistivity and breakdown voltage, which can effectively isolate current and protect the safe operation of circuits and equipment.

Excellent heat resistance: In high temperature environment, bakelite sheet can maintain stable physical and chemical properties, not easy to deform or burn. It is suitable for high temperature working environment.

High mechanical strength: Bakelite sheet treated with high temperature and high pressure has high tensile, compressive and bending strength, and can withstand greater mechanical stress.

Wear resistance and corrosion resistance: Bakelite sheet surface is hard and wear-resistant, and has good corrosion resistance to a variety of chemicals. And it is suitable for harsh working environment.

Good processing performance: Bakelite sheet is easy to cut, drill and process into various shapes and sizes, which is convenient to meet diverse application needs.

The cost of bakelite board is relatively high and the price is relatively expensive;

Compared with metal and other materials, bakelite board is weaker and is not suitable for occasions with heavy loads;

Bakelite board is easily affected by moisture in a humid environment, which affects its insulation performance, so it is not suitable for use in some special environments.

1. Electrical equipment field

Bakelite sheet is an insulating material and is commonly used in various electrical equipment such as traditional electronic equipment, air conditioners, transformers, generators, AC motors, etc. In the production process of electronic products, bakelite sheet is usually used as insulating material, gasket and isolation board. Because bakelite sheet has good mechanical strength and electrical properties, and excellent insulation properties, it can protect the service life and stability of electronic equipment. In addition, the use of bakelite sheet can also improve the safety of electrical products.

2. Petrochemical field

Bakelite sheet is not only widely used in electrical equipment, but also has an important position in the petrochemical field. In this field, bakelite sheet is used as components such as sensors, motor housings, transformer fixtures, explosion-proof switches and partitions. Because bakelite sheet has excellent properties such as heat resistance, stain resistance, and chemical corrosion resistance, it can be used in harsh environments to ensure the stability and safety of industrial production.

1.Mixing of Raw Material

The first step in manufacturing involves the mixing of raw materials in a reactor vessel. Raw materials include phenol, formaldehyde, and fillers such as wood or cotton cloth. A catalyst hydrochloric acid triggers the polymerization reaction while blending. As a result of this reaction, a thermosetting resin is formed.

2.Impregnation of Paper

The next step involves the impregnation of paper with the thermosetting resin. A layer of resin is spread onto the paper and any excess resin is removed by passing it through rollers. The impregnated paper is then dried to remove moisture and prepare it for processing.

3.Lamination

The process of laminating a bakelite board involves arranging several layers of impregnated paper at a right angle to each other. Then, compressing and heating the material produces a hard and inflexible bakelite substance.

4.Curing

The final step in the manufacturing process involves curing. The press subjects the stacked layers of impregnated paper to high temperature and pressure to cure it. This initiates cross-linking in the thermosetting resin. Then the formation of a final product bakelite board becomes completed. This product is a robust, heat-resistant, chemical-resistant material. This material can endure mechanical stress.

1. Use environment

The use environment of bakelite board has a great impact on its performance, such as temperature, humidity and other factors need to be considered. At the same time, factors such as the mechanical environment and workload of the electrical equipment need to be considered.

2. Performance requirements

Select bakelite board with different performance according to the different needs of the equipment, such as heat resistance, insulation performance, wear resistance, etc.

3. Cost considerations

Considering the high cost of bakelite board, it is necessary to comprehensively consider the trade-off between economic benefits and costs.

The price of bakelite sheet is affected by many factors, including material quality, specifications, brand, market supply and demand, and purchase channels. The price of bakelite sheet is generally around 24 to 26 yuan per square meter. If it is a high-performance bakelite sheet, the price may reach several hundred yuan per square meter or even higher.

When you are looking for bakelite sheet manufacturers, ZTelecgroup is your legitimate source.

ZTelecgroup has a 65-year history of producing insulation materials.

In addition, ZTelecgroup has a very high reputation in the field of insulation materials.

In addition to bakelite sheet, ZTelecgroup also has a variety of insulation material products, such as FR4, DDP, etc. You can choose the one that suits you best.

In addition, ZTelecgroup can be customized according to the different needs of customers, and the length and width can also be cut according to customer needs.

Overall, ZTelecgroup can meet the specific requirements of each customer.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……