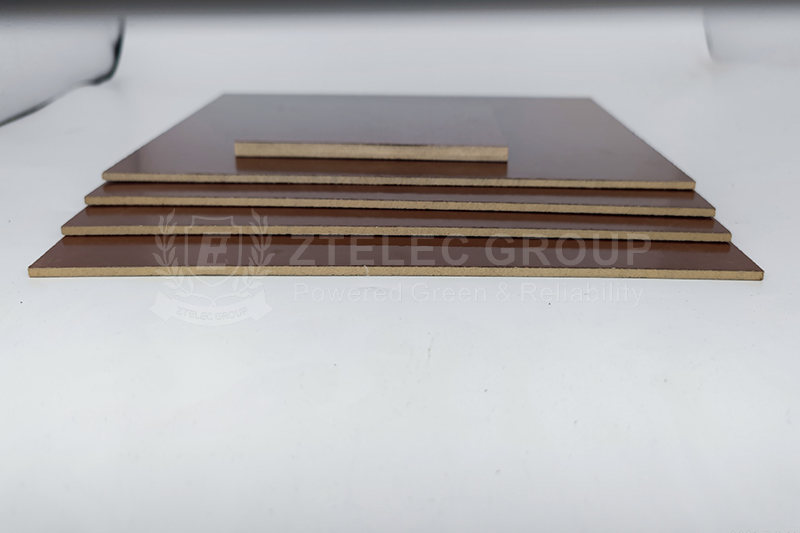

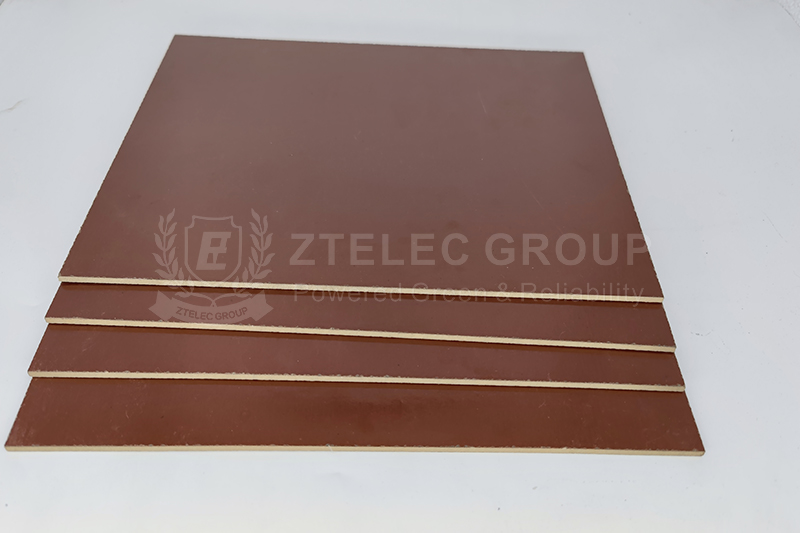

Phenolic sheet, as a high-performance composite material, is mainly made of phenolic resin and insulating paper through impregnation, hot pressing and other processes. This material combines the excellent performance of phenolic resin and the mechanical strength of reinforced fiber, showing a wide range of application potential in construction, electronics, transportation, and other fields.

Electrical insulation sheet: Phenolic insulation sheet is one of the commonly used insulation materials in electrical engineering. They are used to manufacture insulation partitions, insulation gaskets and insulation sleeves for electrical equipment such as switch cabinets, distribution boxes, transformers, etc. These insulation materials can effectively prevent short circuits and leakage accidents of electrical equipment and ensure the safe operation of electrical equipment.

Motor insulation material: In motor manufacturing, phenolic sheets are used as insulation materials for motor stators, rotors and windings. These insulation materials can withstand high temperatures and mechanical stresses during motor operation to prevent short circuits and leakage accidents in motors. At the same time, they can also improve the efficiency and reliability of motors.

Cable sheath: Phenolic sheets are also used to make cable sheaths and insulation layers. These sheaths and insulation layers can effectively protect cables from interference and damage from the external environment, while ensuring the safe transmission of cables.

Fireproof and thermal insulation materials: Phenolic sheets are also widely used in fireproof and thermal insulation. They are used to make thermal insulation materials for building components such as fireproof doors, fireproof windows, and fireproof partitions. These thermal insulation materials can effectively isolate fire sources and heat, preventing the spread and expansion of fires. At the same time, they are also lightweight, non-toxic, and non-corrosive, which is conducive to the evacuation of personnel and the fighting of fires.

Advantages:

Low cost: Compared with epoxy resin (such as FR-4) or polyimide, phenolic sheets have lower production costs.

Easy to process: It can be quickly formed by cutting, drilling, stamping and other processes. It is suitable for mass production.

Good heat resistance: The working temperature can usually reach 120~150℃, and it can withstand higher temperatures in the short term.

Limitations:

Limited temperature resistance: It is easy to age under long-term high temperature and is not suitable for extreme high temperature scenes such as aerospace.

Environmental issues: Traditional phenolic resins may release formaldehyde, and environmentally friendly improved products need to be selected.

Insufficient high-frequency performance: The dielectric loss is high and it is not suitable for high-frequency circuits (such as 5G communication equipment).

Phenolic sheets are widely used in transformers, motors, low-voltage PCBs and industrial equipment due to their low cost, easy processing and reliable insulation performance. Although they are limited in the fields of high temperature resistance and high frequency, their economy and practicality make them continue to occupy an important position in the low-end and mid-end markets. With the advancement of environmental protection technology, phenolic sheets will continue to play an irreplaceable role in the fields of electricity, home appliances, etc.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……