Printed Circuit Boards (PCBs) are crucial components in modern electronic devices. Proper selection and application of insulating materials are essential for the stability and reliability of PCB design and manufacturing. This article will explore common types of insulating materials for PCBs and provide guidance on selecting the appropriate insulation material to meet specific application requirements.

A PCB, or Printed Circuit Board, is a flat board made of non-conductive material (such as fiberglass or composite epoxy) that serves as a base for assembling and connecting electronic components. It provides mechanical support and electrical connections for various electronic elements, such as integrated circuits (ICs), resistors, capacitors, and connectors.

The main purpose of a PCB is to provide a platform for the assembly and interconnection of electronic components in a compact and organized manner. By using a PCB, manufacturers can simplify the assembly process, reduce the size and weight of electronic devices, improve reliability, and minimize electrical interference.

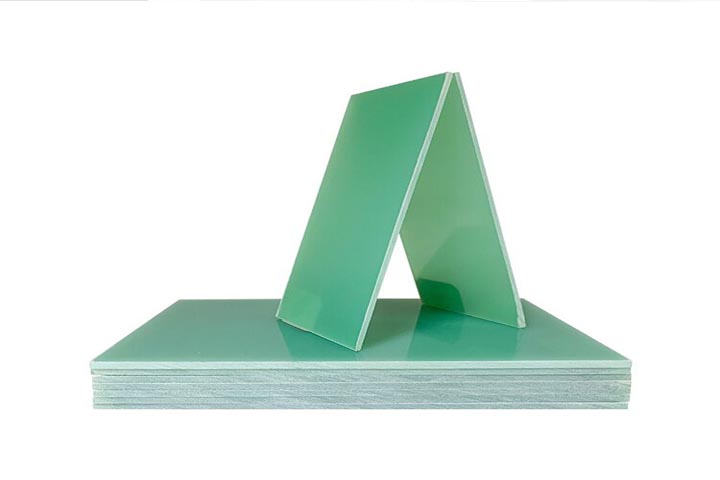

FR-4 is a fiberglass-reinforced epoxy resin substrate widely used in general applications. It offers good electrical insulation properties, mechanical strength, and heat resistance, suitable for most conventional PCB applications.

FR-2 is a paper-based substrate typically used for low-cost single-layer PCBs. It is cheaper than FR-4 but has poorer electrical properties and heat resistance.

High-frequency circuits, such as RF and microwave circuits, require insulating materials with low dielectric constant and loss tangent. Common high-frequency insulating materials include PTFE (Polytetrafluoroethylene), RF-35, and the RO4000 series.

Certain applications demand PCBs to operate in high-temperature environments, necessitating insulating materials with excellent heat resistance. Polyimide (PI) and Polyether Ether Ketone (PEEK) are commonly used high-temperature insulating materials due to their outstanding heat resistance and mechanical strength.

PAI is a high-performance insulating material with excellent mechanical strength, heat resistance, and electrical properties. It is often used in PCBs for aerospace, aviation, and defense applications that require exceptional reliability.

The dielectric constant and loss tangent of insulating materials directly impact the high-frequency performance of PCBs. For high-frequency circuits, it is necessary to select materials with low dielectric constant and loss tangent.

Insulating materials need to have sufficient mechanical strength to support and protect PCBs. In multi-layer PCBs, interlayer bonding strength and impact resistance are particularly important.

In some applications, PCBs need to operate in high-temperature environments. Therefore, selecting insulating materials with good heat resistance is crucial to prevent material failure or performance degradation.

Insulating materials should possess good chemical stability to resist corrosion from acids, bases, and other corrosive substances, ensuring long-term reliability of PCBs.

The cost of insulating materials also needs to be considered. For low-cost applications, selecting lower-priced insulation materials is reasonable, but quality and performance should not be compromised.

Using high-frequency insulating materials in communication equipment enhances signal transmission reliability and stability.

Automotive electronic systems require insulating materials that can withstand high temperatures and vibrations to cope with harsh operating environments.

In industrial control applications, insulating materials with good mechanical strength and chemical resistance are needed to ensure equipment reliability and stability.

Medical devices often require insulating materials with high temperature resistance, chemical resistance, and excellent electrical performance to meet the stringent requirements of the healthcare industry.

In the aerospace and defense sectors, PCBs need to utilize high-performance insulating materials to withstand extreme temperatures, pressures, and vibrations.

With the increasing demands for faster communication and data transmission speeds, insulating materials need to have lower dielectric constants and higher glass transition temperatures to meet higher performance requirements.

As the demand for environmentally friendly materials grows, future insulating materials will trend towards more eco-friendly and sustainable choices, reducing negative impacts on the environment.

Proper selection and application of insulating materials are crucial for the stability and reliability of PCBs. Choosing the appropriate insulation material based on specific application requirements is key to ensuring proper functioning of PCBs in various operating environments. As technology continues to advance, insulating materials will continue to improve in performance and expand their applicability to meet the evolving needs of the electronics industry. Throughout the PCB design and manufacturing process, it is essential to prioritize the selection of insulating materials and continually strive for better solutions to ensure the quality and reliability of PCBs.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……