Densified Laminated Wood is made by cutting fine birch wood into thin strips and then heat pressing and laminating them together. It has the advantages of moderate density, high mechanical strength, easy vacuum drying, and ease of processing. Its dielectric constant is close to transformer oil, making it an excellent insulating material.

Densified Laminated Wood has several advantages, including the following aspects:

With a dielectric constant similar to transformer oil,Densified Laminated Wood is an outstanding insulating material. This characteristic makes it widely used in electrical equipment and electronic devices.

The surface ofDensified Laminated Wood has a low friction coefficient, providing good performance in applications that require sliding or movement. It is an ideal choice for mechanical components, bearings, and sliding surfaces.

Densified Laminated Wood has a high oil absorption capacity, making it perform exceptionally well in lubrication and sealing applications. It effectively absorbs and stores lubricating oil, reducing wear and friction and extending equipment lifespan.

Densified Laminated Wood possesses high mechanical strength and rigidity, capable of withstanding heavy loads and stress without deformation or fracture. It is widely used in structural components, vehicle parts, and building materials.

Densified Laminated Wood exhibits a low thermal conductivity, giving it an advantage in applications that require thermal insulation. It reduces heat conduction and losses, providing better thermal isolation.

Densified Laminated Wood maintains stable performance under extreme temperature conditions and is resistant to deformation, expansion, or contraction. It is suitable for various environments and application scenarios.

Densified Laminated Wood, as a versatile material, finds wide application in various fields. Here are several typical application areas:

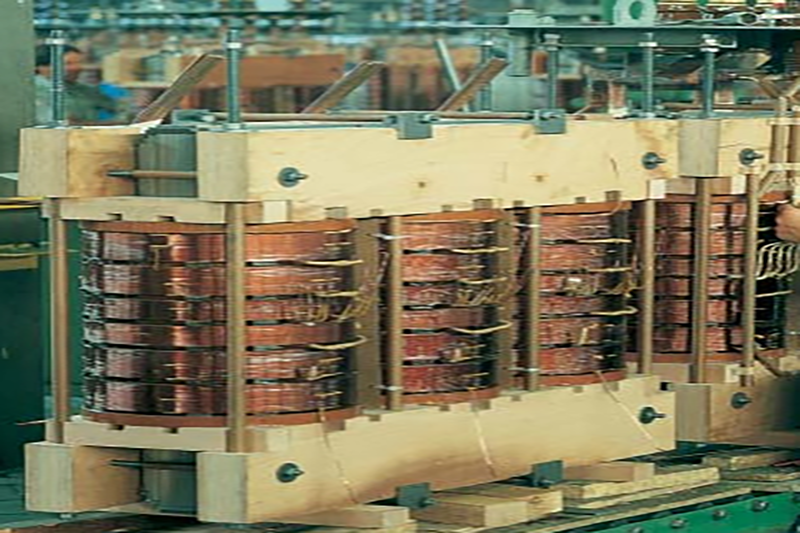

Its excellent electrical insulation and mechanical strength make it a high-performance insulating material used to wrap iron cores between coils, ensuring proper current conduction and providing good insulation performance.

In the manufacturing process of electronic devices,Densified Laminated Wood is commonly used as the base material for solder pads and lead frames. Its low sliding friction coefficient and excellent mechanical properties make it a reliable support material capable of withstanding thermal and mechanical stress during the soldering process.

Densified Laminated Wood is employed in transformer construction as insulation gaskets, partitions, and coating materials, ensuring safe operation and efficient performance. Its excellent electrical insulation, high-temperature resistance, and low thermal conductivity make it an ideal choice for transformer components.

Densified Laminated Wood is widely used in the manufacturing of inductors. It serves as the insulating housing and supporting structure, offering stable electrical insulation performance and mechanical strength, protecting internal components, and ensuring accurate signal transmission and efficient operation.

These application areas represent only a portion ofDensified Laminated Wood’s potential uses, as it also plays a crucial role in other fields such as insulation materials, mechanical parts, and building materials. Its outstanding performance makes it a reliable choice for various industrial and commercial applications.

We manufacture a wide range of insulation components for various types of transformers. With our team of professional researchers and experts, we can help you understand the selection of insulation materials and component designs. Whether it’s for large liquid-filled transformers, dry-type distribution transformers, or low-voltage electronic transformers, we are here to provide guidance and offer sincere recommendations. We also offer customizations to meet your specific needs. If you require any assistance, please don’t hesitate to contact us.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……