G11 board, as a high-performance insulation material, plays a vital role in many fields such as electronics, aerospace, transportation, etc. Due to its unique composition and superior performance characteristics, G11 board needs to follow a series of strict technical specifications during processing and molding to ensure the quality and application effect of the final product.

The processing of G11 board first requires careful preparation and strict proportioning of raw materials. The raw materials mainly include glass fiber cloth and epoxy resin. Glass fiber cloth should be alkali-free or low-alkali type to ensure its good corrosion resistance and strength. Epoxy resin needs to select the appropriate model and curing agent according to the specific application requirements to ensure that the cured board has the required mechanical and electrical properties.

During the proportioning process, the amount of epoxy resin and the addition ratio of curing agent need to be strictly controlled. Too much epoxy resin may cause the board to be too thick and insufficient hardness, while too little epoxy resin may cause the board to be weak and brittle. Therefore, accurate proportioning is the key to ensuring the quality of G11 board.

Impregnating the prepared fiberglass cloth in epoxy resin is an important step in the processing of G11 board. During the impregnation process, it is necessary to ensure that the fiberglass cloth is fully impregnated with epoxy resin to avoid dry spots or uneven impregnation. After the impregnation is completed, the impregnated fiberglass cloth is dried to remove excess resin and solvent, and at the same time partially cure the resin to enhance the initial strength of the board.

The temperature and time need to be strictly controlled during the drying process to avoid over-curing or under-curing of the resin. Over-curing may cause the board to become brittle, while under-curing may affect the electrical and mechanical properties of the board.

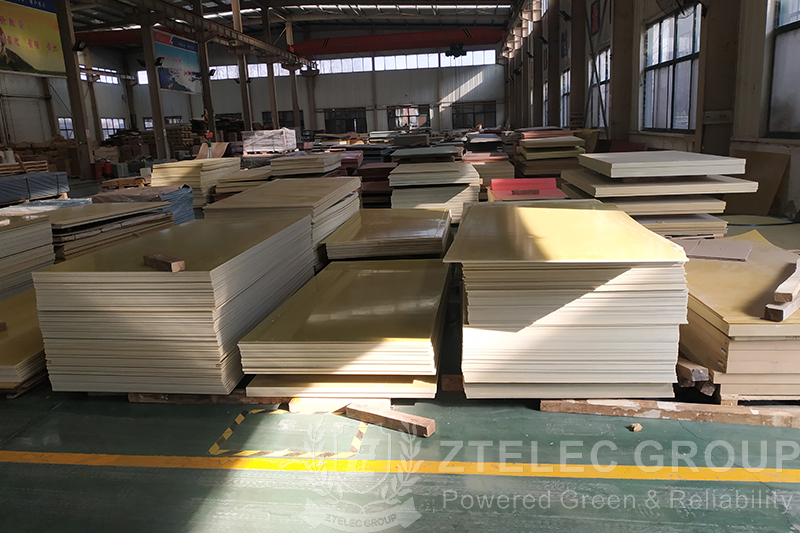

The impregnated and dried glass fiber cloth is hot pressed on a hot press. Hot press is one of the key steps in the processing of G11 board, which determines the final shape and dimensional accuracy of the board. During the hot pressing process, parameters such as temperature, pressure and time need to be strictly controlled.

The choice of temperature should be determined according to the curing temperature range of epoxy resin to ensure that the resin is fully cured and forms good interlayer bonding. The pressure should be sufficient to make the glass fiber cloth fit tightly and discharge excess resin and gas, while avoiding deformation or cracking of the board. The time control should be determined according to the curing rate of the resin and the thickness of the board to ensure that the curing process is fully carried out.

High-precision processing: With the increasing demand for high-precision parts in the electronics and aerospace fields, the high-precision processing technology of G11 boards will be further developed. Use advanced CNC machine tools and laser processing technology to improve processing accuracy and efficiency.

Green manufacturing: Promote environmentally friendly coolants and lubricants to reduce the impact on the environment. Develop low-energy and low-pollution processing technology to support sustainable development.

Intelligent processing: Integrate intelligent control systems, monitor the processing process in real time, and automatically adjust processing parameters. Use artificial intelligence technology to optimize processing paths and processes to improve processing quality and efficiency.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……