There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

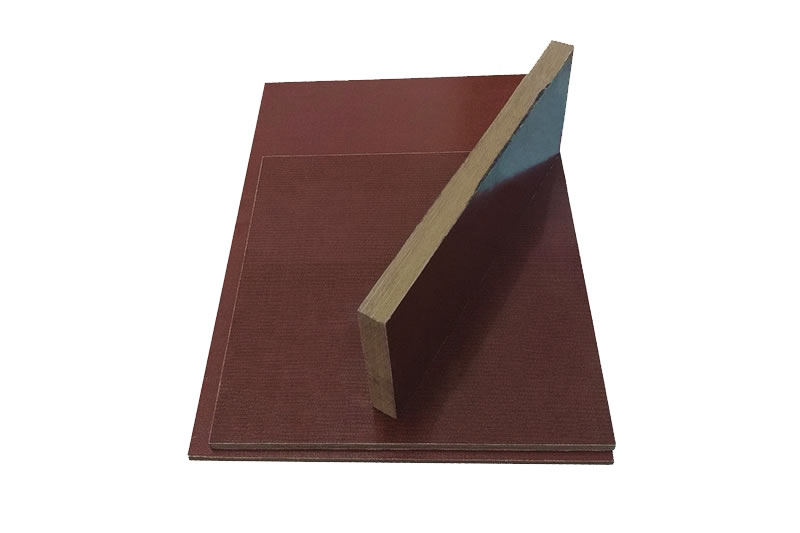

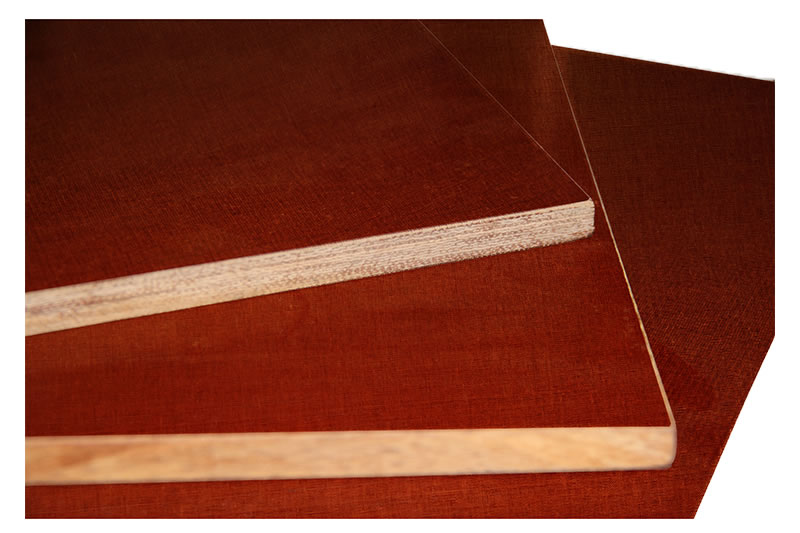

Phenolic cotton cloth sheet is made of cotton cloth impregnated with phenolic resin, baked and hot pressed. The heat resistance rating is E. With high mechanical properties, oil resistance and dielectric properties, phenolic cloth boards have high mechanical strength, excellent moisture resistance and heat resistance, good electrical properties (poor board), and are easy to process.

Email:[email protected] Whatsapp:+8613137718313

Phenolic cotton cloth sheet is made of cotton cloth impregnated with phenolic resin, baked and hot pressed. The heat resistance rating is E. With high mechanical properties, oil resistance and dielectric properties, phenolic cloth boards have high mechanical strength, excellent moisture resistance and heat resistance, good electrical properties (poor board), and are easy to process. Phenolic cloth boards are widely used in electrical products. Phenolic laminated paper and cloth board have a density of about 1.5g / ㎝, which is lighter than aluminum and is used in aerospace and other structures.

Phenolic cotton cloth sheet Thickness from 1mm to 80mm,inculding several color of orange,coffee,light brown. The product has stable quality and is easy to process. It can be processed into various parts by lathe processing, stamping, trimming, drilling, sawing and milling.

1) High electrical and mechanical performance.

2) Easy for fabrication, good dimentional stability, physical strength, resiliency.

3) Better machinability than other products.

| Standard | GB/T 1303-2009/ IEC60893-2003 | ||||||

| Basic Information | Chinese Name | 3025 | 3025A | 3026 | 3027 | 3021 | |

| IEC | PFCC201 | PFCC202 | PFCC203 | PFCC305 | PFCP201 | ||

| Basic Material | Cloth | Paper | |||||

| Resin | Phenolic | Phenolic | |||||

| Color | Brown | Red Brown | |||||

| No. | Test Item | Unit | Value | Value | |||

| 1 | Density | g/m³ | 1.3~1.4 | 1.25~1.4 | |||

| 2 | Vertical Layer Bending Strength(normal) | Mpa | ≥100 | ≥90 | ≥110 | ≥125 | ≥120 |

| 3 | Parallel Layer Impact Strength (simply supported beam method) |

KJ/m² | ≥7.8 | ||||

| 4 | Vertical Layer Electrical Strength (90℃ transformer oil)(1mm thickness) | Kv/mm | ≥5.1 | ≥5.1 | ≥5.1 | ≥5.1 | ≥15.8 |

| 5 | Parallel Layer Breakdown Voltage (90℃ transformer oil) | kv | ≥20 | ≥35 | |||

| 6 | Dielectric Constant (50Hz) | – | ≤5.5(1MHZ) | ≤5.5(1MHZ) | |||

| 7 | Insulation Resistance after Immersion | Ω | ≥5*107 | ≥5*107 | |||

| 8 | Proof Tracking Index(PTI) | – | ≥100 | ≥100 | |||

| 9 | Temperature Index | – | 120 | 120 | |||

| 10 | Water Absorption (1-20mm thickness) | mg | 206~406 | 136~277 | 180~970 | ||

| Note: Range values are measured for different thicknesses | |||||||

Phenolic cotton cloth sheet is a common industrial material with good electrical properties and mechanical strength, and is widely used in the electrical and electronic industries. The following are some of the main uses of phenolic cotton cloth sheet:

Electrical insulation: Due to its excellent electrical insulation performance, phenolic cotton cloth sheetis often used to manufacture insulating components in various electrical equipment, such as transformers, motors, switchgear, etc.

Mechanical processing: Phenolic cotton cloth sheethas high mechanical strength and wear resistance, and can be drilled, cut, engraved and other mechanical processing to make parts of various shapes.

Printed circuit sheet(PCB): In the production process of multi-layer printed circuit sheets, phenolic cotton cloth sheetis one of the commonly used substrates, especially in occasions requiring high heat resistance and electrical performance.

Electrical equipment: Used to make the shell and internal components of electrical tools and test instruments to provide protection and insulation.

Semiconductor packaging: In the field of semiconductor packaging, phenolic cotton cloth sheetcan be used to manufacture packaging materials, providing good thermal stability and electrical insulation.

Furniture manufacturing: In some furniture manufacturing, phenolic cotton cloth sheetcan be used as surface decoration material or structural parts because of its smooth surface, wear resistance and easy cleaning.

Building materials: Phenolic cotton cloth sheethas certain waterproof and fireproof properties and can be used as partitions, ceiling materials, etc. in buildings.

Transportation: In the manufacture of vehicles such as cars and trains, phenolic cotton cloth sheetcan be used to manufacture interior parts, sound insulation and heat insulation materials, etc.

Aerospace: In the field of aerospace, phenolic cotton cloth sheetcan be used to manufacture some lightweight and high-strength parts because of its good high temperature resistance and corrosion resistance.

In the application of bearing and gear materials:

the use of phenolic cotton plate reduce the sound of machine operation and reduces noise compared with ordinary metal materials.

In addition, when running, there is no spark, so it can replace metal materials in explosion-proof environment.Phenolic cotton cloth board products are suitable for manufacturing various gears,rollers, pulleys and guide rails.

The processing of phenolic cotton cloth board usually includes the following steps:

1.Raw material preparation:

Phenolic resin: as a binder, used to bond cotton cloth together.

Cotton cloth: as a reinforcing material, providing mechanical strength and stability.

2.Impregnation:

The cotton cloth is immersed in the phenolic resin solution so that the resin evenly penetrates into the cotton cloth fiber. This step is to enhance the heat resistance and mechanical strength of the cotton cloth.

3.Pre-curing:

The impregnated cotton cloth is preliminarily heated and cured to form a semi-finished product with a certain hardness and stability.

4.Lamination:

Multiple layers of pre-cured cotton cloth are stacked together and laminated under high temperature and pressure. This process will completely cure the phenolic resin and tightly bind the layers of cotton cloth together to form an integral board.

5.Cooling and trimming:

After lamination, the board is cooled to room temperature. Then trimming is performed to remove the uneven edges to ensure the dimensional accuracy and flatness of the board.

6.Quality inspection:

Carry out quality inspection on the processed phenolic cotton cloth board to check whether its physical and chemical properties meet the standard requirements. For example, test its electrical insulation performance, mechanical strength, heat resistance, etc.

7.Packaging and storage:

Qualified products are packaged and stored in a dry and ventilated environment to prevent moisture and damage.

we are factory direct sales,no middlemen make the difference,product ship directly from our factory,saving costs and time from the source.Welcome to contact us and isit our factory .Let us do better and better.

We are steadily growing upinto aleading enterpriseof electrical equipment with an international brand in China.We are IS09001,IS014001and 0HSAS18000 certified.With 60years’experi-

ence,a sound quality control system and the consummate after-sales service,we win a high reputation both at home and abroad.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 60 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first. Products are exported to Europe, America, Southeast Asia and other countries and regions.

If you need to know more about phenolic resin sheets and other insulation materials product information and quotations, please contact us, we can mail you samples for your testing

1.Where is your factory?

Our factory is in Xuchang city, Henan province, China.

2.Can I visit your factory?

Of course, welcome to our factory.

3.Can you send me samples to test?

Yes, we offer free samples to customers and they just need to pay the freight.

4.Do you have any certificates for your products?

Yes, we have UL certificate, SGS, ISO 9001: 2008 etc.

5.What ’s your payment terms?

Usually our payment terms is 30% paid by T / T in advance and the balance paid before shipment. This is negotiable.

6.What ’s your delivery time?

It depends on the product and order quantity. Usually the delivery time is within 15 working days after getting deposit.

7.What ’s your main product?

We supply all kinds of insulation materials used in electrical field and most of them used in transformers and motors.

If you need our products please write down any questions, we will reply as soon as possible.