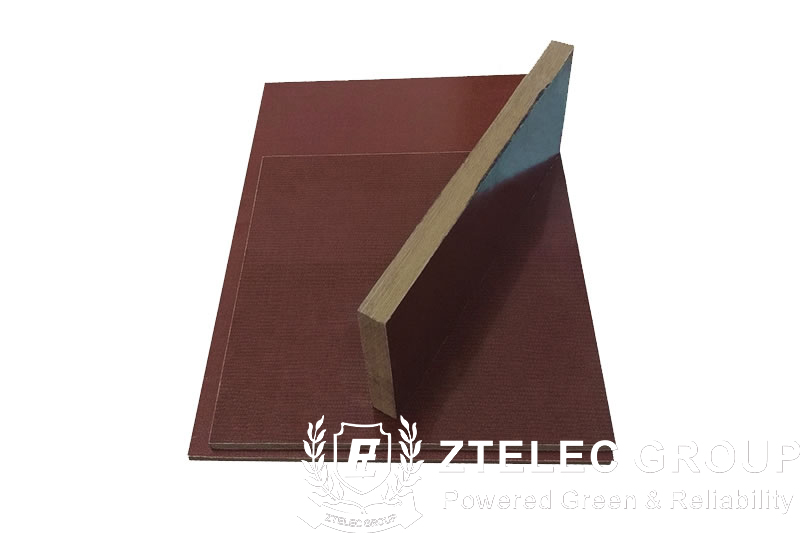

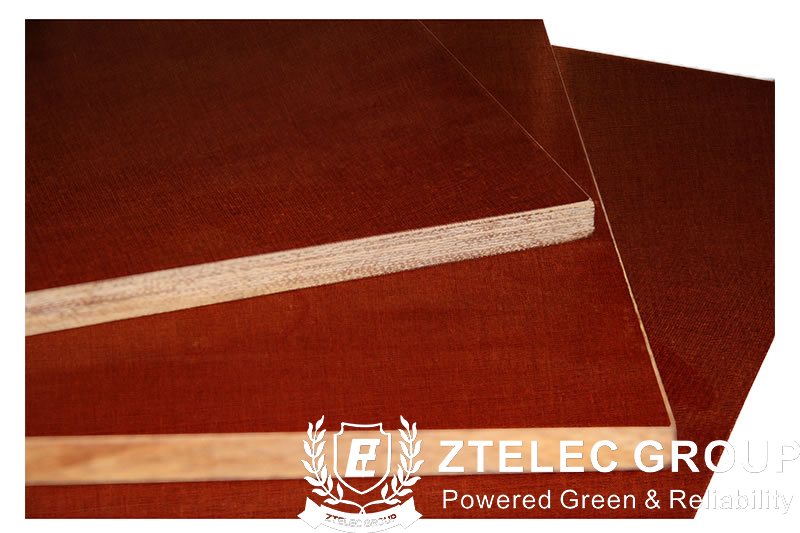

Phenolic cotton cloth sheet is a kind of laminate material made of cotton cloth impregnated with phenolic resin and then dried and hot pressed. Cotton cloth is used as reinforcing material to provide strength and toughness of the material; phenolic resin is used as matrix material to bond and cure the cotton cloth.

Surface flatness: The surface of phenolic cotton cloth sheet should be flat, no bubbles, pockmarks and impurities. But a small number of spots are allowed.

Excellent mechanical properties: Phenolic cotton cloth sheet has high mechanical strength and toughness. It is suitable for use as insulating structural parts in all kinds of machinery, motors and electrical equipment.

Oil resistance: It can be used in transformer oil and has good oil resistance.

Heat resistance: It has a certain heat-resistant grade. And it is suitable for use in high-temperature environments.

The processing of phenolic cotton cloth sheet usually includes the following steps:

Phenolic resin: It is used as an adhesive for bonding the cotton cloth together.

Cotton cloth: It acts as reinforcing material to provide mechanical strength and stability.

Curing agent: Select a suitable curing agent according to the type of phenolic resin and processing conditions.

Catalysts, preservatives and fire retardants: These additives are used to improve the properties of phenolic cotton cloth sheets, such as accelerating curing, improving corrosion resistance and fire resistance.

The cotton cloth is dipped into the phenolic resin solution so that the resin penetrates evenly into the cotton fibers. This step is to enhance the heat resistance and mechanical strength of the cotton cloth.

Preliminary heating and curing of the impregnated cotton cloth to form a semi-finished product with a certain degree of hardness and stability.

Multiple layers of pre-cured cotton cloth are stacked together and laminated under high temperature and pressure. This process will make the phenolic resin completely cured, and the layers of cotton cloth will be tightly combined together to form a whole sheet.

After the lamination is completed, the sheet is cooled to room temperature. It is then trimmed to remove uneven edges and ensure the dimensional accuracy and flatness of the sheet.

Conduct quality inspection on the processed phenolic cotton cloth sheet to check whether its physical and chemical properties meet the standard requirements. For example, test its electrical insulation properties, mechanical strength, heat resistance and so on.

Package the qualified products and store them in a dry and ventilated environment to prevent moisture and damage.

In addition to the basic processing methods mentioned above, Phenolic cotton cloth sheet can also be processed by some special processing methods to improve its performance or to meet specific application requirements. For example:

Modified phenolic resin: The use of modified phenolic resin as an adhesive can improve certain properties of phenolic cotton cloth sheets, such as improving temperature resistance, corrosion resistance or reducing costs.

Adding fillers: Adding appropriate amount of fillers, such as asbestos, aluminum silicate, etc., to the resin can further improve the strength and toughness of phenolic cotton cloth sheet.

Surface treatment: Surface treatment of phenolic cotton cloth sheet, such as coating fireproof coating, corrosion-resistant coating, etc., can further improve its fire performance and corrosion resistance.

The processing technology of phenolic cotton cloth sheet is constantly developing and improving, providing high-quality material support for electrical insulation, machinery manufacturing, aerospace and other fields. In the future, with the continuous progress of science and technology and the continuous expansion of application areas, the processing technology of phenolic cotton cloth sheet will usher in more innovation and development opportunities.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……