NMN insulation material usually consists of three layers: a layer of polyester film in the middle (also said to be made of polyimide film) and Nomex paper on both sides. Both Mylar and polyimide films have good dielectric strength and heat resistance, while Nomex paper is known for its excellent high temperature resistance, flame retardant and mechanical toughness. The close combination of these three layers of materials makes NMN excellent in both electrical and mechanical properties.

1.Heat resistance: The heat resistance grade of NMN insulation materials is usually F (155 ° C), and some products can even reach H (180 ° C) or higher. This means that it can maintain stable insulation performance in high temperature environments and will not lose insulation due to temperature rise.

2.Mechanical properties: The material has high strength and excellent edge tear resistance and can withstand large mechanical stresses without breaking. This makes it able to withstand a variety of complex mechanical stresses in the manufacture of electrical equipment such as motors and transformers to ensure the stable operation of the equipment.

3.Electrical properties: NMN insulation materials have excellent electrical strength and can maintain insulation properties under high voltage. Its smooth surface helps to achieve trouble-free operation during the production process and ensures the safe operation of electrical equipment.

4.Flame retardant properties: Nomex paper, as an important part of NMN insulation materials, has excellent flame retardant properties. When in contact with the flame, the NMN insulation material can resist burning or prevent further burning when leaving the flame, thus effectively preventing the occurrence of fire accidents.

5.Corrosion resistance: NMN insulation materials also have good corrosion resistance and can resist the erosion of various corrosive substances to ensure the stable operation of electrical equipment in harsh environments.

NMN insulation materials are widely used in many fields because of their excellent properties:

1.Motor manufacturing: NMN insulation material is one of the important materials in motor manufacturing, mainly used for motor slot, slot cover and phase insulation. It can withstand various mechanical and electrical stresses during the operation of the motor to ensure the stable operation of the motor.

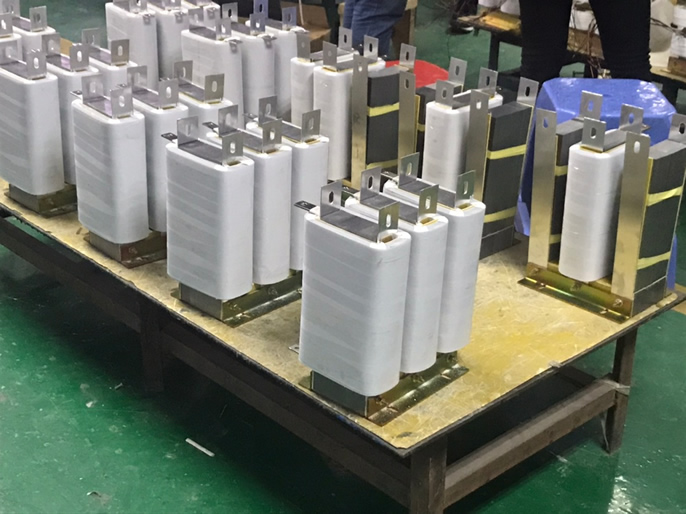

2.Transformer manufacturing: In transformer manufacturing, NMN insulation materials are mainly used for interlayer insulation to improve the insulation performance and safety of transformers.

3.Other electrical equipment: In addition, NMN insulation materials can also be used as insulation and support materials for other electrical equipment, such as capacitors, resistors, etc. Its excellent performance and wide range of applications make it an irreplaceable position in the field of electrical equipment manufacturing.

The production process of NMN insulation materials usually includes steps such as raw material preparation, compounding, calender, cutting and inspection. In the production process, the quality of raw materials and process parameters need to be strictly controlled to ensure that the performance of the product meets the requirements. At the same time, it is also necessary to carry out strict inspection and testing of the finished product to ensure its reliable quality and stable performance.

During storage and transportation, NMN insulation materials need to be kept dry, ventilated and sheltered from light. Avoiding contact with fire, heat sources and humid environments is to avoid damage to its performance. At the same time, it is also necessary to pay attention to prevent mechanical damage and extrusion deformation to ensure the integrity and performance stability of the product.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……