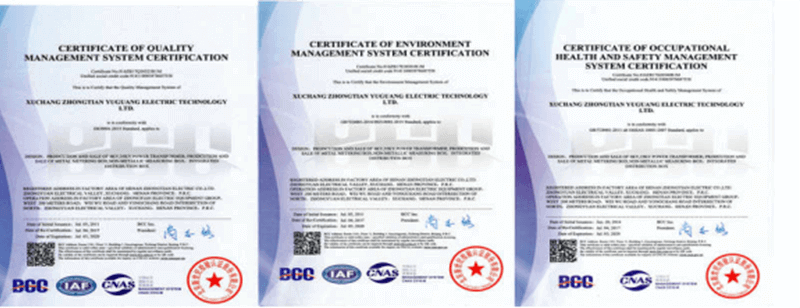

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

Heat resistance rating: Class F(155 ° C)

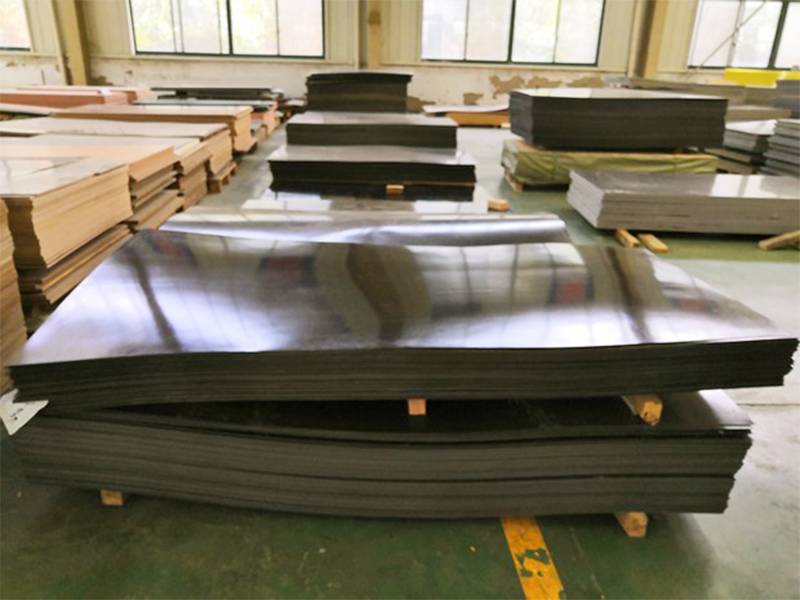

Thickness: 12-1000mm

Size: 3500*1000 /2000*1000 /2000*4000, support customization

Density:1.0-1.1,1.1-1.2,1.2-1.3

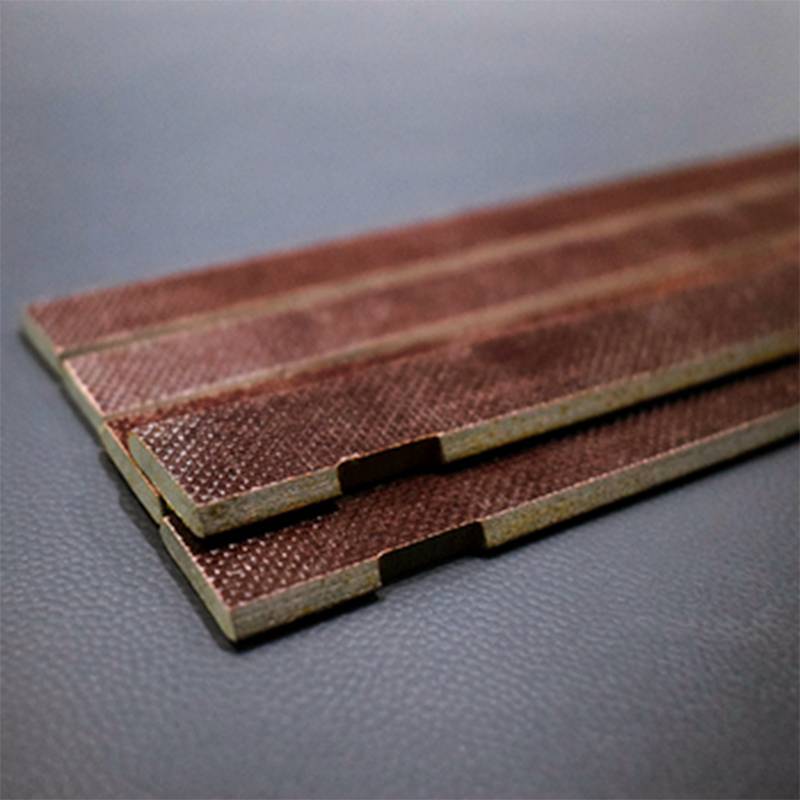

Color: Brown

Email:[email protected] Whatsapp:+8613137718313

The magnetic conductive fiberglass sheet is made of the following raw materials by weight: composite resin 100, amine curing agent 3 to 35, curing accelerator 0.05 to 2, soft magnetic material 370 to 400, glass fiber cloth 60 to 100, antioxidant 0.7 to 1.5. The manufacturing method of the magnetic conductive fiberglass sheet is formed by a lamination method, and the pre-cured sheet is formed by one-time sizing of the alkali-free glass fiber cloth or the electrical fiberglass cloth, the composite resin, and the magnetic material, and the prepreg is superimposed and pressed into a magnetic conductive sheet. The laminated magnetic conductive plate of the invention has high magnetic permeability, excellent mechanical properties, good processing performance and long service life, and is suitable for processing magnetic wedges of various types of motors.

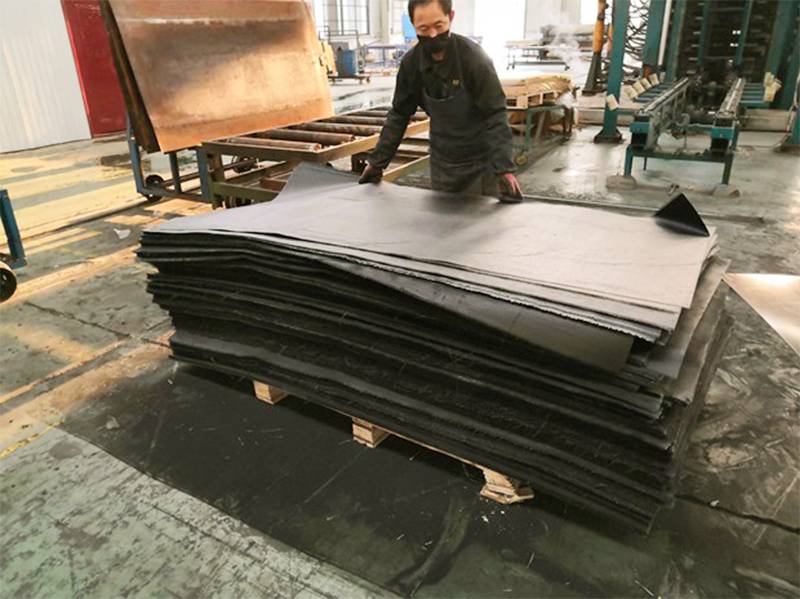

The magnetic conductive fiberglass sheet has high magnetic permeability, excellent mechanical properties, good processing performance and long service life. Here you can have a look of the Magnetic conductive fiberglass sheet. Here is the video, you can have a look.

| NO. | Properties | Unit | Index | ||||

| DLW101 | DLW201 | DLW202 | DLW301 | ||||

| 1 | Appearance | – | Smooth Surface, Neat Edge Cutting, No Layered Cross-section | ||||

| 2 | Density | g/cm³ | 1.2-1.3 | 1.1-1.2 | 1.1-1.2 | 1.0-1.1 | |

| 3 | Vertical Bending Strength | A Direction | MPa | ≥80 | ≥65 | ≥65 | ≥55 |

| B Direction | ≥80 | ≥65 | ≥65 | ≥55 | |||

| 4 | Impact Strength | A Direction | KJ/m2 | ≥15 | ≥13 | ≥13 | ≥10 |

| B Direction | ≥15 | ≥13 | ≥13 | ≥10 | |||

| 5 | Interlaminar

Shear Strength |

MPa | ≥9 | ≥8 | ≥8 | ≥7 | |

| 6 | Vertical Electrical Strength

(90℃ transformer oil) |

Kv/mm | ≥9 | ≥8 | ≥7 | ≥7 | |

| 7 | Parallel Breakdown Voltage

(90℃ transformer oil) |

kv | ≥50 | ≥50 | ≥50 | ≥50 | |

| 8 | Contamination to Liquid Dielectric | – | ≤0.1 | ||||

| 9 | Shrinkage after Drying | A Direction | % | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

| B Direction | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | |||

| Thickness Direction | ≤3 | ≤3 | ≤3 | ≤3 | |||

| 10 | Water Content | % | ≤6 | ≤6 | ≤6 | ≤6 | |

| 11 | Oil Absorption | % | ≥5 | ≥8 | ≥8 | ≥10 | |

| Application Scope of Laminated Wood Insulating | Transformer | ≤110KV | ≥110KV | 66-35KV | ≥ 35KV | ||

The magnetic conductive fiberglass sheet has high mechanical properties and heat resistance, and a certain permeability, is the raw material of the magnetic wedge. Used in large motors and wind turbines.

The magnetic conductive fiberglass sheet has high magnetic permeability, excellent mechanical properties, good processing performance and long service life.

Wrapped with packaging film and packed in pallet; horizontally placed in dry and clean room at room temperature; keep it away from moisture and fire. The storage period is 12 months.

Here is the certificate of our insulation materials and factory, which can ensure the quality of the products which supply to our customers. In 2011, we obtained the certificates of ISO9001:2008 International Quality Management System, and ISO14001 organization environmental management system. Products including Power Distribution Cabinet, HV Switchgear, Transformer Substation, Complete Switchgear and power transformers (below 35kV) passed the tests from CNAS, IAC-MRA, AL, CMA and others international testing organizations.

1. Pre-sales service

We offer 1V1 personal service and our professionals will provide you with technical guidance and free samples.

2. After sales service

Our staff will communicate with you on a regular basis and any insulation issues can be consulted in a timely manner.

3. Product Service

We offer product size customization and product processing services.

1. Is ZTELEC a manufacturer?

A: ZTELEC is a Chinese manufacturer of insulating materials and was founded in 1958.

2. Do you support custom?

A: We can customize the products according to customer needs and support the processing parts.

3. Is the sample free?

A: Our samples are free, but require the customer to bear the shipping costs.

4. Is there a spot?

A: Our warehouse maintains stocks throughout the year and some sizes can be shipped within a week.

If you need our products please write down any questions, we will reply as soon as possible.