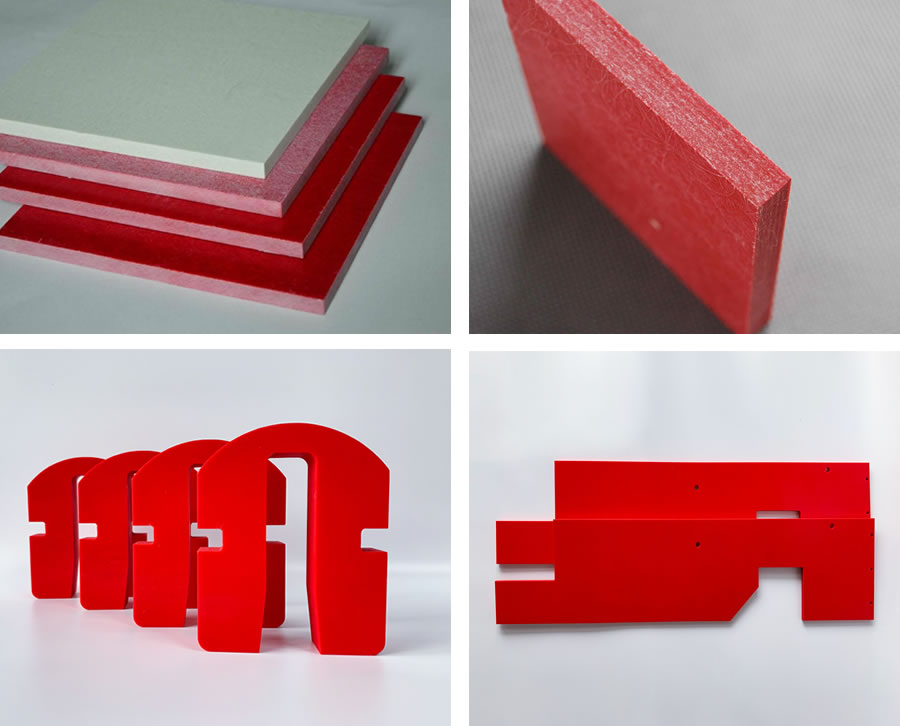

GPO-3 sheet is a hard plate-shaped insulation material made of alkali-free glass fiber felt board impregnated with unsaturated polyester resin paste and added with corresponding additives through hot pressing. It refers to unsaturated polyester glass fiber felt board material, which is used for mechanical and electrical purposes. It has good electrical properties under high humidity, good mechanical properties under medium temperature, flame retardancy, good arc resistance and resistance to leakage traces.

Specifications: 1000*2000* (thickness 2-30) mm, 1020*1220* (thickness 0.8-10) mm, 1000*1200* (thickness 3-50) mm, 1200*2500* (thickness 3-45) mm

Color: white, brown-red, etc. (color can be customized for large quantities)

Electrical insulation: All electrical insulation laminates are natural high-quality insulators. Here, according to the grade characteristics, using its *special properties, it is widely used in electrical engineering and technology.

1. Flame retardant performance: Grades 1580 and UTR are UL-rated V-0. Grade UTR does not contain halogens, and the system produces very little smoke and toxic fumes in the event of a fire.

2. Mechanical strength: High-strength glass fiber reinforced polyester laminates will not shatter. Rigid laminates provide structural support due to their isolation properties. Flexible laminates can be used in applications with a small bend diameter of 19mm.

3. Heat resistance: Laminates provide excellent protection and dimensional stability during heating. These laminates have UL temperature ratings in the range of 120-210℃ electronic and 130-210℃ mechanical.

4. Easy to form: These materials can be easily processed and formed using standard metal handling equipment. They can be stamped, drilled, machined, sheared and sanded. Grade UTR is well known for its easy high-speed processing in machining centers. Grade 1580 punches cleanly and quickly.

5. Those that produce smoke are inferior products. The product has very good adhesion, and the material itself is environmentally friendly and does not produce smoke.

6. Toxic gas is produced. Inferior products generally use flame retardants to achieve flame retardant effects, so there are pungent poisonous gases when burning. As the flame retardant evaporates, the product performance also decreases. It cannot be used in environments with human contact and hot environments.

7. Combustion stratification. Due to the irregular structure of glass fiber felt, the mechanical tension of GPO-3 comes from the inside, and internal stratification will not occur during high-temperature carbonization. If there is stratification during combustion, it is an inferior product.

8. Withstand voltage: 3mm thickness ≥25KV, 4mm thickness ≥33KV, 5-6mm thickness ≥42KV, 7-10mm thickness ≥48KV, 10mm thickness ≥60KV.

1. Application in circuit breakers: frame circuit breakers: safety baffles, safety shields, spacer pads, phase partitions, etc.

2. Application in molded case circuit breakers: phase partitions, arc extinguishing chamber arc partitions, etc.

3. Application in motors: motor armature parts, movable cover plates, slot wedge stators, fixed gaskets, thin gaskets, carbon brush holders, etc.

4. Application in switchgear: front end, rear end, top end, bottom end, phase partitions, etc. in partition systems Other applications: arc-resistant structural parts.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials with more than 60 years of manufacturing experience. If you need more product information and quotes, please contact us.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……