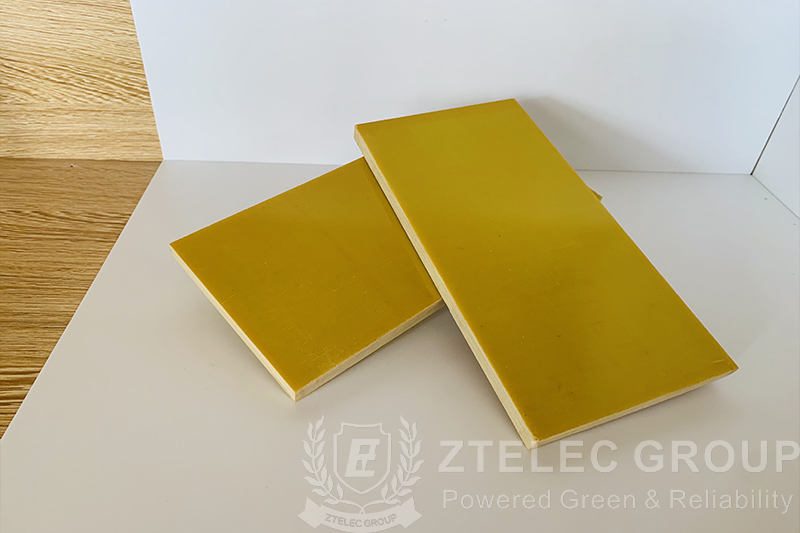

G11 sheet is a board made of alkali-free glass fiber cloth as a reinforcement material, impregnated with epoxy resin, and then laminated and cured under high temperature and high pressure. It is a type of epoxy glass cloth laminate and a high-performance insulation material. The name of G11 sheet comes from the NEMA (National Electrical Manufacturers Association) standard, where “G” represents fiber glass reinforcement and “11” represents its specific performance level.

The main components of G11 sheet include:

Alkali-free fiber glass cloth: As a reinforcement material, it provides high mechanical strength and dimensional stability.

Epoxy resin: As a matrix material, it provides excellent electrical insulation performance and chemical resistance.

Additives: Such as flame retardants, stabilizers, etc., they are used to improve the flame retardancy, heat resistance and other properties of the material.

Excellent electrical properties: G11 sheet insulation material has high insulation resistance and low dielectric constant, which can effectively prevent the flow of current and reduce the propagation of electromagnetic waves in the material, thus providing good electrical insulation performance.

Excellent mechanical properties: G11 sheet insulation material has high density, tensile strength and bending strength, and can withstand large tensile and bending loads without breaking easily. This allows G11 sheet to maintain stable performance under various mechanical stresses.

Excellent heat resistance: The glass transition temperature and heat deformation temperature of G11 sheet are high, and it can maintain good mechanical properties and insulation properties under high temperature conditions. In addition, G11 sheet also has good flame retardant properties, which can effectively prevent the spread of flames in fire.

Good chemical resistance: G11 sheet can resist the erosion of common organic solvents and acid and alkali substances, and has a long service life. This allows G11 sheet to maintain stable performance in chemical environments.

Due to its excellent performance, G11 sheet is widely used in many fields, mainly including:

1. Electronic and electrical industry

Transformer insulation parts: G11 sheet is used to manufacture insulation parts in transformers, such as slot wedges, partitions, etc.

Circuit board support parts: In high-frequency circuit boards, G11 sheet is used as a support material to provide good insulation and mechanical strength.

Switch equipment: G11 sheet is used to manufacture insulation parts in switch equipment, such as circuit breakers, relay bases, etc.

2. Aerospace field

Structural parts: G11 sheets are used to manufacture structural parts in aircraft and spacecraft, such as brackets, partitions, etc.

Insulating parts: In aerospace equipment, G11 sheets are used as high-performance insulating materials to ensure the reliability of equipment in extreme environments.

3. Chemical and environmental protection equipment

Corrosion-resistant equipment: G11 sheets are used to manufacture corrosion-resistant parts in chemical equipment, such as storage tanks, pipelines, etc.

Environmental protection equipment: In environmental protection equipment, G11 sheets are used as supporting materials for filters and separators.

With the continuous advancement of science and technology and the accelerated advancement of industrialization, G11 sheet will be widely used in more fields, providing strong support for modern social construction and industrial production.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……