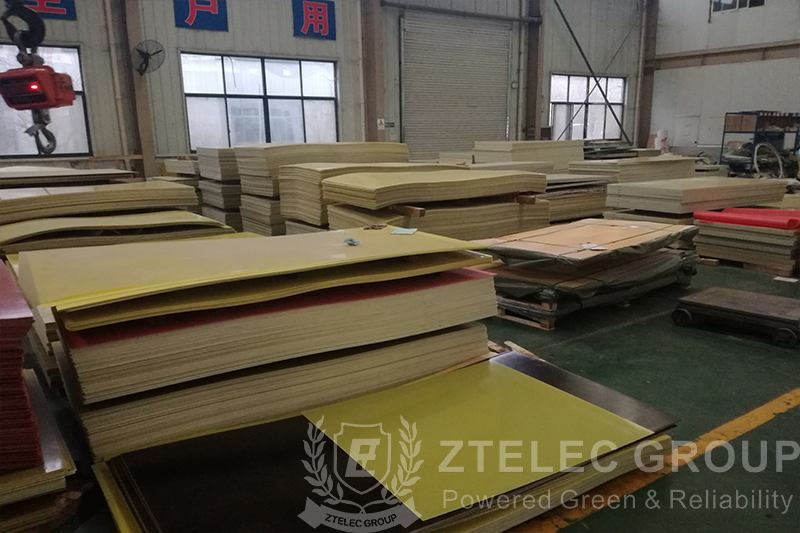

G11 board, as a high-performance epoxy glass cloth laminate, is widely used in electronics, electrical, aerospace and other fields. Due to its excellent electrical insulation performance, mechanical strength and heat resistance, it is crucial to choose the right supplier and high-quality materials.

G11 board price is affected by many factors:

1. Material Specifications

Thickness: The thicker the material, the higher the price. For example, a 10mm thick G11 board will cost more than a 5mm thick one.

Size: Standard sizes (e.g. 1000mm × 2000mm) are usually less expensive, and custom sizes may increase the cost.

Color: Natural (light yellow) is the most common color, and custom colors (e.g. black, green) may increase the price.

2. Material quality

Brand and certification: Well-known brands or G11 boards certified by UL, RoHS, etc. are more expensive, but the quality is more guaranteed.

Performance level: G11 boards with high performance (such as low dielectric loss and high heat resistance) are usually more expensive.

3. Purchase quantity

Bulk purchase: Large-volume purchases can usually enjoy discounts and reduce unit prices.

Small-volume purchases: Small-volume or sample purchases are more expensive, but are suitable for initial testing and verification.

4. Supplier Type

Manufacturer: Purchasing directly from the manufacturer is usually cheaper, but may require a minimum order quantity (MOQ).

Distributor: Purchasing from a distributor offers more flexibility, but prices may be slightly higher.

5. Market Supply and Demand

Raw Material Price Fluctuations: Fluctuations in the prices of raw materials such as epoxy resin and fiberglass can affect the price of G11 boards.

Market Demand: When market demand is high, prices may rise.

When looking for high-quality G11 board, you can follow the following steps:

1.Clear demand: First, clarify your own procurement needs, including material specifications, quantity, delivery time, etc. This will help you to target suppliers more precisely.

2.Market research: Understand the market situation and supplier situation of G11 boards through market research. You can obtain information by consulting relevant industry reports, consulting professionals, or participating in industry exhibitions.

3.Supplier screening: Screen out a list of potential suppliers based on market research results. During the screening process, pay attention to the supplier’s qualifications, product quality, delivery time and price.

4.Sample testing: Request samples from the screened suppliers for testing. The test content can include the mechanical properties, dielectric properties, insulation properties and other aspects of the material. The test can verify whether the quality of the material meets the requirements.

5.Price and delivery time: Inquire multiple suppliers for prices, compare prices, and select the supplier with the best cost-effectiveness. Understand the supplier’s delivery capacity and ensure on-time delivery.

6.After-sales service: Choose a supplier that provides technical support to facilitate solving problems during use. Understand the supplier’s after-sales policy to ensure that quality problems can be solved in a timely manner.

ZTelecgroup is an enterprise with 65 years of insulation material production history. It has a complete industrial chain and also has a high reputation in the industry. If you need more product information and quotation, please contact us.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……