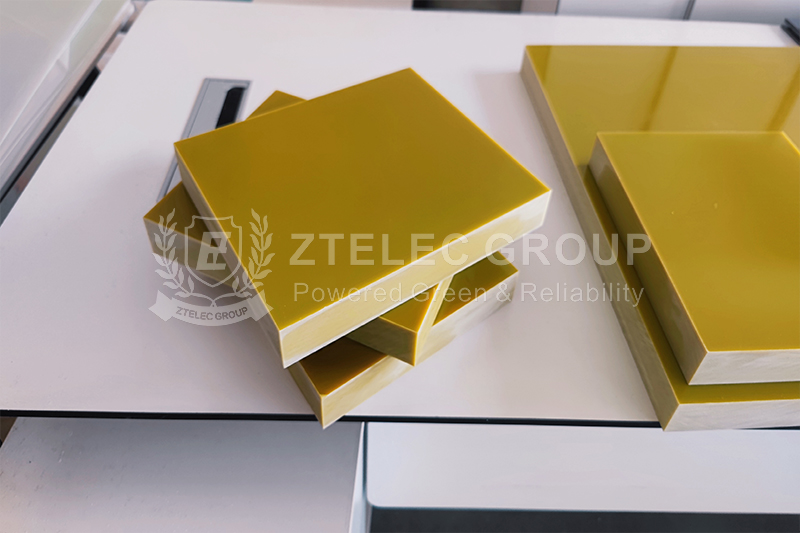

In the field of materials science, G10 and G11, as representatives of glass fiber and resin laminated composite materials, have attracted much attention due to their unique properties and wide range of applications. These two materials not only perform well in electrical insulation, mechanical strength, heat resistance, etc., but also become the first choice in many industrial fields due to their good processing performance and corrosion resistance.

G10 and G11 materials are both glass fiber and resin rolled composite materials, and their basic composition includes glass fiber cloth, epoxy resin and various additives.

Glass fiber cloth: G10 and G11 both use imported electronic grade alkali-free glass fiber cloth as reinforcement material. This kind of glass fiber cloth has the characteristics of high strength, high modulus, corrosion resistance, wear resistance, etc., which can effectively improve the overall performance of composite materials.

Epoxy resin: As a matrix material, epoxy resin plays a role in bonding glass fiber cloth, transferring load and providing certain performance in G10 and G11. Different types of epoxy resin have a significant impact on the performance of composite materials, so G10 and G11 may differ in the choice of epoxy resin.

Additives: In order to improve the performance of composite materials, flame retardants, adhesives, curing agents and other additives are added to G10 and G11. The types and proportions of these additives have an important impact on the flame retardancy, processability, heat resistance and other properties of composite materials.

Heat resistance: Both G10 and G11 materials have good heat resistance. They can maintain stable performance at higher temperatures without deformation or damage. However, due to the optimization of G11 material in resin additives, its structural strength at high temperatures is higher, so G11 may have slightly better heat resistance than G10.

Flame retardant performance: Both G10 and G11 materials have good flame retardant properties. The flame retardant grade of G10 material is usually UL94-V2 (some say UL94-VO, which may be related to different manufacturers or test standards), while the flame retardant grade of G11 material generally reaches UL94-VO. This means that G11 may be better in flame retardant performance and can maintain stable performance at higher temperatures or in harsher environments.

Mechanical properties: Both G10 and G11 materials show good mechanical properties at high temperatures. They have high tensile strength, bending strength, and compressive strength, and can withstand large loads without damage. In addition, both materials have good fatigue resistance and wear resistance, and can maintain stable performance during long-term use.

Processing performance: Both G10 and G11 materials have good processing performance. They can be processed by cutting, drilling, grinding and other processes to meet the needs of different shapes and sizes. In addition, these two materials also have good adhesion and plasticity, and can be well combined and formed with other materials.

G10 and G11 are used as insulating structural parts in motors and electrical equipment, such as circuit breakers, switch cabinets, transformers, DC motors, AC contactors, explosion-proof electrical appliances and other electrical appliances. However, G11 can be used in humid environments and transformer oil. G11 can also be used in high-voltage switchgears, high-voltage switches, etc.

As representatives of glass fiber and resin laminated composite materials, G10 and G11 materials have performed well in terms of composition, performance characteristics and application areas. Although there are some differences between them, each has its own unique advantages and characteristics. When choosing to use, comprehensive consideration should be made based on specific application scenarios and needs to select the most suitable material.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……