In today’s rapidly evolving technological landscape, various innovative materials are making their mark. One such material is G10. Its unique properties and applications have captured the attention of engineers, designers, and enthusiasts alike. In this blog post, we will delve into the world of G10, uncovering its meaning, features, manufacturing process, advantages, limitations, and diverse range of applications.

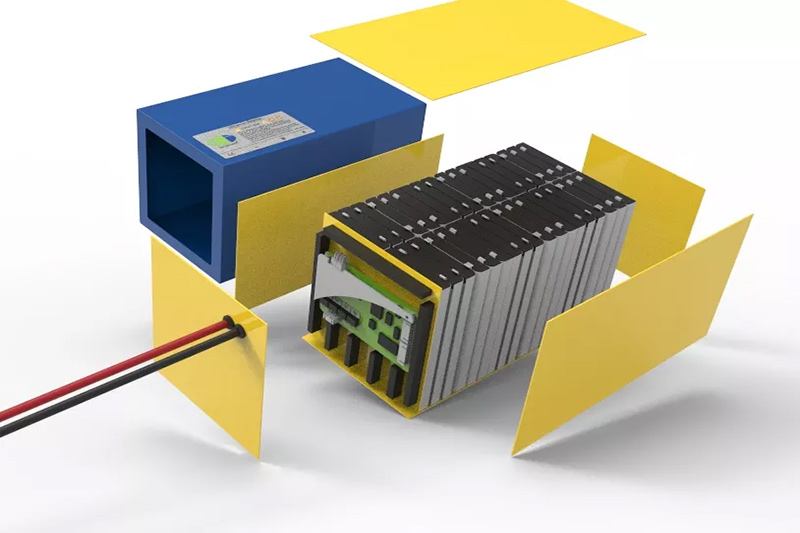

G10 sheet is a type of laminated composite material comprised of layers of fiberglass cloth impregnated with epoxy resin. The combination of these materials results in a durable and versatile product with exceptional mechanical properties. G10 is renowned for its high strength, excellent electrical insulation capabilities, and resistance to environmental factors such as moisture, chemicals, and extreme temperatures.

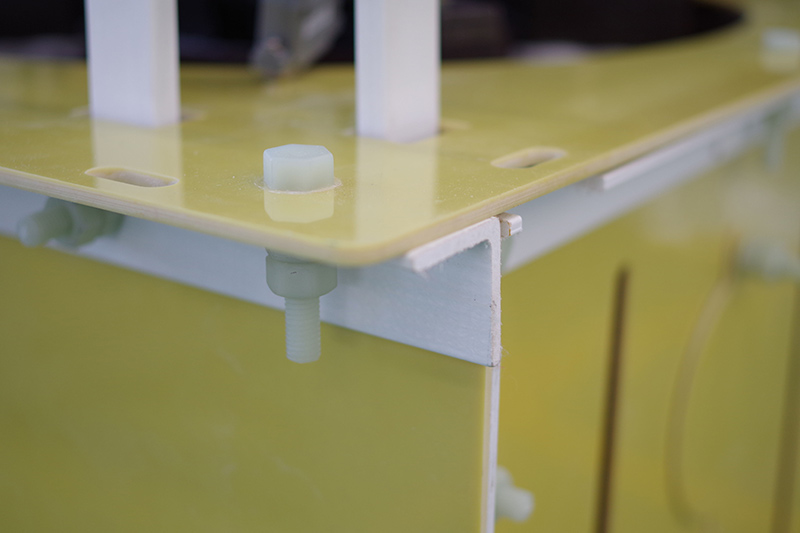

The foundation of G10 sheet lies in the layers of fiberglass cloth. These thin but robust sheets are saturated with epoxy resin, which acts as a binder to hold them together. The resin impregnation ensures a solid and cohesive structure, providing the desired attributes to the final product. The number of layers used can vary, depending on the specific requirements of the application.

G10 sheet, made from layers of fiberglass cloth impregnated with epoxy resin, offers a wide range of advantages that have contributed to its growing popularity in various industries.

One of the primary advantages of G10 sheet is its exceptional strength-to-weight ratio. Despite being lightweight, G10 sheet exhibits remarkable mechanical strength, making it suitable for applications requiring robust and durable components. It can withstand heavy loads and impacts without compromising its integrity, ensuring reliable performance and longevity.

G10 sheet possesses excellent electrical insulation capabilities, making it an essential material for electrical and electronic applications. Its high dielectric strength and low conductivity ensure proper isolation and protection against electrical hazards. This makes G10 sheet ideal for manufacturing insulating components, circuit boards, and other electrical insulation applications.

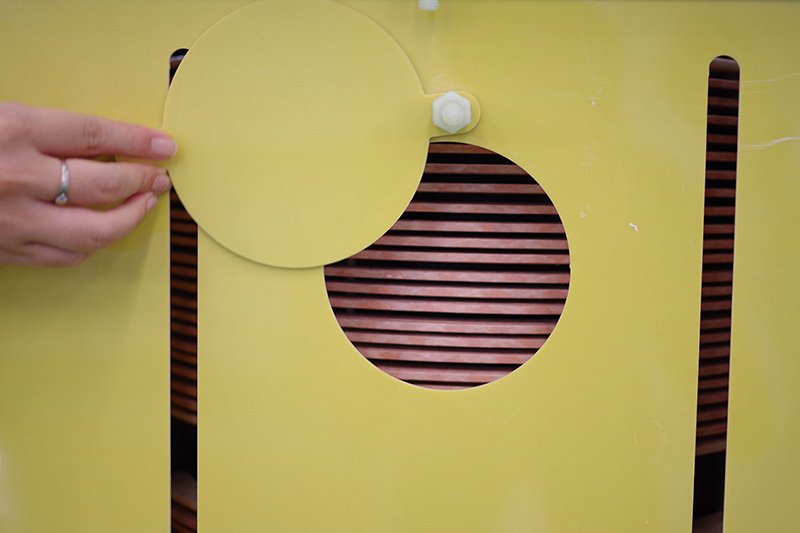

G10 sheet demonstrates impressive resistance to environmental factors such as moisture, chemicals, and extreme temperatures. It has low water absorption, which prevents degradation and ensures dimensional stability even in high-humidity or wet environments. Additionally, G10 sheet is resistant to a wide range of chemicals, including acids and bases, further enhancing its durability and reliability. Its ability to withstand extreme temperatures makes it suitable for applications exposed to heat or cold.

Another advantage of G10 sheet is its versatility and the ability to be customized for specific requirements. The manufacturing process allows for precise control over the thickness, size, and surface finish of the sheets, enabling tailored solutions for different applications. G10 sheet can be easily machined, drilled, and cut into desired shapes and sizes, providing flexibility to accommodate unique project needs.

G10 sheet exhibits excellent resistance to corrosion, making it suitable for applications where exposure to corrosive substances or environments is a concern. Unlike metals that may rust or corrode over time, G10 sheet maintains its structural integrity and performance even in harsh conditions, ensuring long-term reliability.

While G10 sheet offers a range of exceptional benefits, it also has certain limitations that should be taken into consideration for specific applications.

One of the primary limitations of G10 sheet is its inherent brittleness. Compared to some other materials, such as metals or plastics, G10 sheet is more prone to cracking or chipping under high impact loads. This makes it less suitable for applications that require high toughness or resistance to sudden impacts. It is important to assess the specific requirements of the project and consider whether the brittleness of G10 sheet aligns with the intended application.

During the manufacturing process of G10 sheet, epoxy resin is used as a binder for the layers of fiberglass cloth. It should be noted that epoxy resin can emit volatile organic compounds (VOCs) during production, which can pose potential health risks if not properly managed. Adequate ventilation and safety precautions should be implemented in the working environment to minimize exposure to VOCs and ensure the wellbeing of workers involved in the production or handling of G10 sheets.

While G10 sheet is known for its versatility and customization options, it can present challenges during machining processes. Due to its robust nature and high mechanical strength, G10 sheet can be difficult to machine compared to softer materials. Cutting, drilling, or shaping G10 sheet may require specialized tools or techniques to achieve precision and desired results. It is essential to work with experienced professionals who are familiar with the unique characteristics of G10 sheet to ensure proper machining and avoid damages or compromising the material’s integrity.

G10 sheet serves as a fundamental material in the manufacturing of circuit boards. It acts as a substrate or base material upon which electronic components are mounted. The high dielectric strength and low conductivity of G10 sheet ensure proper insulation between different circuit layers and prevent electrical short circuits.

G10 sheet is extensively used in electrical connectors to provide insulation and mechanical stability. Its superior electrical insulation properties enable secure and reliable connections between conductive elements while preventing leakage or interference. G10 sheet’s dimensional stability ensures long-term performance and resistance to environmental factors.

Terminal blocks, used for connecting multiple wires in electrical systems, often rely on G10 sheet for insulation. G10 sheet acts as an insulating barrier between metal contacts, preventing electrical contact and ensuring proper wire termination. It enhances safety by minimizing the risk of short circuits and electrical malfunctions.

G10 sheet finds application in the production of transformers and inductors, where electrical isolation is essential. It provides insulation between the primary and secondary windings in transformers, ensuring efficient energy transfer. G10 sheet’s thermal stability, high breakdown voltage, and resistance to moisture make it an ideal choice for these critical components.

G10 sheet acts as an effective insulating material for capacitors, which store electrical energy. It prevents the flow of current between conductive plates and ensures optimal capacitor performance. G10 sheet offers stable insulation properties over a wide range of temperatures and frequencies, making it suitable for various capacitor applications.

Within printed circuit boards (PCBs), G10 sheet is utilized as an insulating material between conductive traces to prevent short circuits. It provides a reliable barrier between different layers or sections of the PCB, enabling complex circuit designs and efficient signal flow. G10 sheet’s durability and dimensional stability ensure longevity in demanding PCB applications.

G10 sheet is employed in the construction of electrical enclosures to provide insulation and protection. It acts as an insulating layer between the internal components and the exterior environment, safeguarding against electrical shock and contamination. G10 sheet’s resistance to moisture, chemicals, and extreme temperatures enhances the durability and reliability of electrical enclosures.

G10 has garnered a well-deserved reputation as an exceptional composite material, highly regarded for its remarkable strength, unmatched durability, and exceptional electrical insulating properties. Its diverse range of applications has revolutionized multiple industries. Whether it’s enhancing the performance of electronic devices or providing reliable structural components, G10 continues to shape the landscape of modern engineering. Currently, our factory has a substantial inventory, so if you have any products in need, please contact us, and we will offer you the highest quality service!

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……