There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

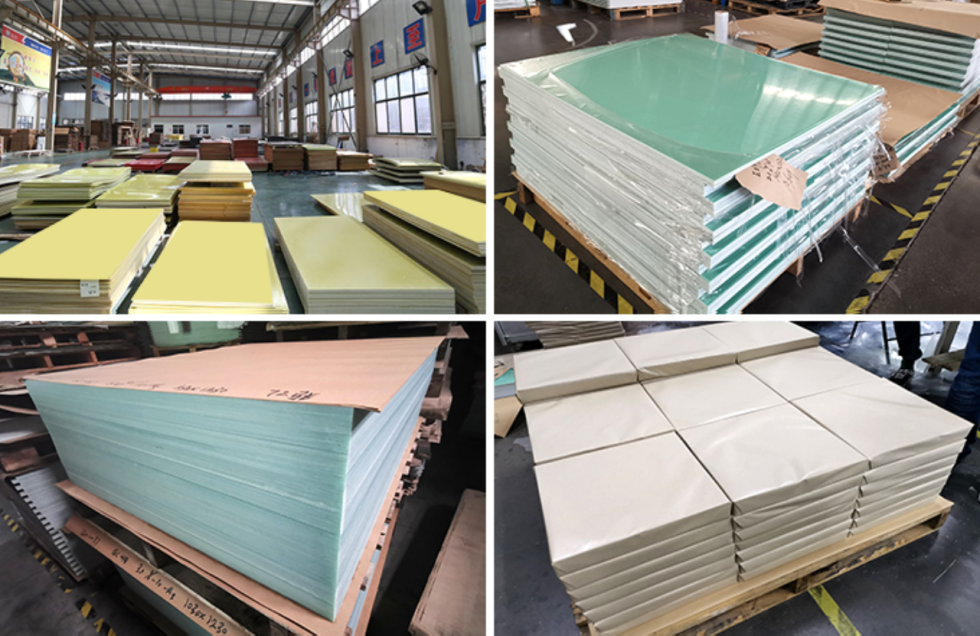

Description: G10 material, also known as fiberglass board, g10 sheet, glass laminate, garolite g10, etc.

Specifications: IEC 60893-3:2003, EPGC 201

Dimensions: 1020*1220mm/1020*2040mm

Thickness: 0.5-100mm

Color: Yellow/Water Green/Black/Customized

Sample: Sample support

Email:[email protected] Whatsapp:+8613137718313

What is G10 sheet material?

“G” stands for glass fiber and “10” generally refers to 10% of glass fiber. G10 sheet material has the characteristics of insulation, corrosion resistance and wear resistance.

G10 sheet material is a composite material composed of glass fiber cloth and epoxy resin. It was originally developed as a material for aircraft and can withstand great forces without damage and deformation.

G10 sheet will not be penetrated by water vapor and liquids. It has the characteristics of insulation, acid and alkali resistance, and is not heavy. G10 sheets are generally available in black, red, blue, green and other colors.

G10 sheet material a high strength Class B rigid insulation with many uses ranging from slot wedges in small motors to major components in turbo-alternators and electronic applications. G10 has excellent moisture resistance and heat resistance, good machining property at room temperature, and excellent electrical performance in dry and wet state.

The matrix resin of G10 is usually epoxy resin or other high-performance polymers. These matrix resins are closely combined with glass fibers to form a composite material that is both strong and lightweight. The choice of matrix resin directly affects the overall performance of G10 material, such as strength, rigidity, corrosion resistance, etc.

1.High strength and rigidity

2.Excellent electrical insulation properties

3.Chemical resistance, moisture resistance, and heat resistance

4.Dimensional stability

5.Fire resistance

| Slot Wedges | Machine parts | Transformer baffles |

| Terminal Boards and Tag Strips | Bolt Insulation | Electromechanical Components |

| High-Voltage Switches | FPC Reinforcing Sheets | Wiring Boards |

| Planetary Gears | Electronic Insulation Fields | Power Distribution Cabinets |

| General Properties: | ||

| Property | Unit of measure | Typical Value |

| Density | g/cm3 | 1.98-2.08 |

| Water Absorption (5mm) | % | ≤0.06 |

| Flame Retardant | UL94 | HB |

| Electrical Properties: | ||

| Property | Unit of measure | Typical Value |

| Electrical Strength ⊥ | kV/mm, thickness<3mm | ≥10 |

| Electrical Strength ∥ | kV | ≥35 |

| Tracking Resistance | PTI | ≥200 |

| Mechanical Properties: | ||

| Property | Unit of measure | Typical Value |

| Benging Strength | MPa | ≥400 |

| Tensile Strength | MPa | ≥300 |

| Compressive Strength ⊥ | MPa | ≥300 |

| Modulus Of Elastricity | MPa | ≥24000 |

| Impact Strength ∥ | kJ/m2 | ≥33 |

| Thermal Properties: | ||

| Property | Unit of measure | Typical Value |

| Thermal Charactersitices | ℃ | 130 |

| Slot Wedges | Machine parts | Transformer baffles |

| Terminal Boards and Tag Strips | Bolt Insulation | Electromechanical Components |

| High-Voltage Switches | FPC Reinforcing Sheets | Wiring Boards |

| Planetary Gears | Electronic Insulation Fields | Power Distribution Cabinets |

G10 material is made of high Pressure Glass Fiber Laminate Board is a type of composite material. It is made by stacking multiple layers of glass cloth, impregnating them with epoxy resin, and then compressing the material under heat until the epoxy resin cures.

The lifespan of G10 is very long, depending on the application and conditions. While exposure to sunlight may shorten its lifespan, when used internally in machinery, it is virtually permanent.

Wrapped with packaging film and packed in pallet; horizontally placeed in dry and clean room at room temperature; keep it away from moisture and fire. The storage period is 12 months.

Yes, we have obtained ISO9001, ISO 14001, and UL certifications. Samples for testing purposes are available.

Yes, we support customization. We can provide one-on-one customization based on specific requirements and ensure timely and quality processing of custom orders.

If you need our products please write down any questions, we will reply as soon as possible.