G10 material is a high-performance composite material that has attracted much attention in the industrial and electronic industries for its unique properties and wide range of applications. This article will provide readers with a complete G10 reading guide from multiple perspectives.

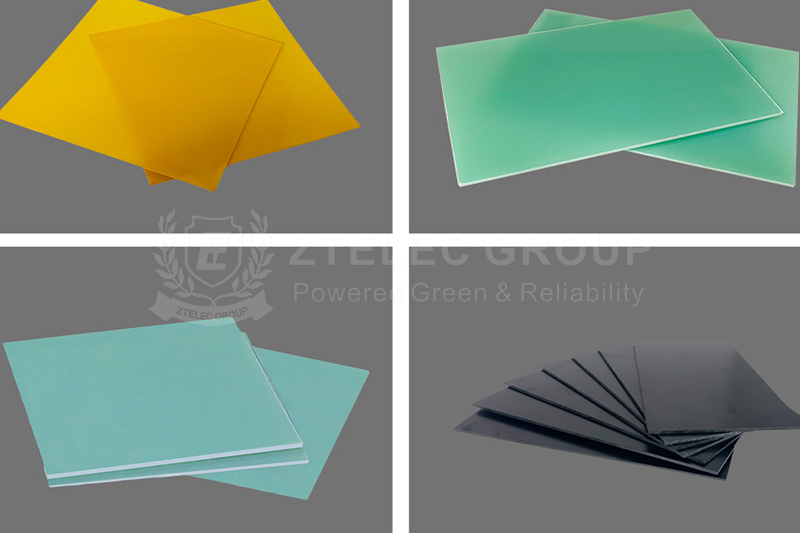

G10 material is made of glass fiber cloth and epoxy resin. Glass fiber cloth acts as a reinforcing material, giving G10 material excellent mechanical strength and stability; epoxy resin, as a matrix material, brings good adhesion and electrical insulation performance to G10 material.

Glass fiber is an inorganic non-metallic material with high strength, corrosion resistance, high temperature resistance and other characteristics. In G10 material, glass fiber cloth exists in a multi-layer woven form and forms a solid skeleton structure of the board, which provides solid support for the whole just like the steel frame of a building.

Epoxy resin is a thermosetting resin with excellent adhesion, electrical insulation and chemical stability. When preparing G10 material, epoxy resin is impregnated with glass fiber cloth, which is then dried and hot-pressed to form a dense board structure just like putting on a strong and insulating “coat” for the skeleton.

G10 is made by mixing together epoxy, fibers, and a hardener. This is then coated over glass fabric to create prepreg, glass fabric impregnated with epoxy resin. The fabric can then be cut and pressed together to create a material with a variety of unique properties.

High mechanical strength: The mechanical strength of G10 is significantly higher than that of ordinary insulation material. Thanks to the reinforcement of its glass fiber cloth, G10 can withstand greater mechanical loads.

Excellent insulation performance: G10 has extremely high dielectric strength and low dielectric constant, which is suitable for use as an insulation material for high voltage and high frequency circuits.

Good temperature resistance: G10 can work for a long time in an environment up to 155°C, and it is suitable for applications in high temperature environments.

Chemical corrosion and moisture resistance: This material performs well in humid or chemically polluted environments and is suitable for electrical equipment that needs to operate under these conditions.

Relatively high cost: Due to its high-performance characteristics, the cost of G10 is higher than some other types of insulation materials, which can be a limiting factor for some budget-sensitive projects.

Motors and electrical equipment: G10 is often used as an insulation structural component in F-class motors and electrical equipment, especially in high humidity environments. Its dielectric properties are stable and suitable for the insulation needs of various motors and electrical equipment.

High-voltage electrical appliances: G10 is also widely used in high-voltage electrical appliances, such as electrolytic aluminum insulation slots, transformers, capacitors, reactors, high-voltage switches, etc. These applications require that the material can still maintain stable mechanical strength and electrical properties under high voltage and high humidity conditions.

Other electronic equipment: G10 is also suitable for other electronic equipment, such as insulation components in power equipment, to ensure safe and stable power transmission.

First, G10 has excellent insulation performance, which can effectively isolate the arc risk caused by high-voltage current and prevent equipment from short circuiting or catching fire.

Second, its high temperature resistance (long-term working temperature can reach above 180°C) enables it to maintain structural stability in high temperature environments and extend the life of the equipment.

In addition, G10 also has good mechanical properties and acid and alkali resistance, waterproof characteristics. It can remain stable in harsh environments.

G10 is a good insulator. G10 is a composite material made of glass fiber cloth and epoxy resin. It was originally developed for use in aircraft and can withstand great forces without deformation. This material has the characteristics of insulation, acid and alkali resistance, and is not penetrated by moisture or liquids. It is also lightweight.

When selecting G10 materials, you should consider its density, hardness, heat resistance, electrical insulation and other performance indicators, and choose according to the specific application scenario. At the same time, you should also pay attention to the quality of the material, the reputation of the manufacturer and the applicability of the product.

During the use of G10 materials, you should pay attention to avoid long-term exposure to high temperature or humid environment to avoid affecting its performance. In addition, you should also avoid contact with corrosive substances such as strong acids and strong alkalis to avoid chemical reactions that may cause material performance degradation.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……