If you need more information and quotes on G11 products, please leave a message below or contact us. We can mail you free samples for testing..

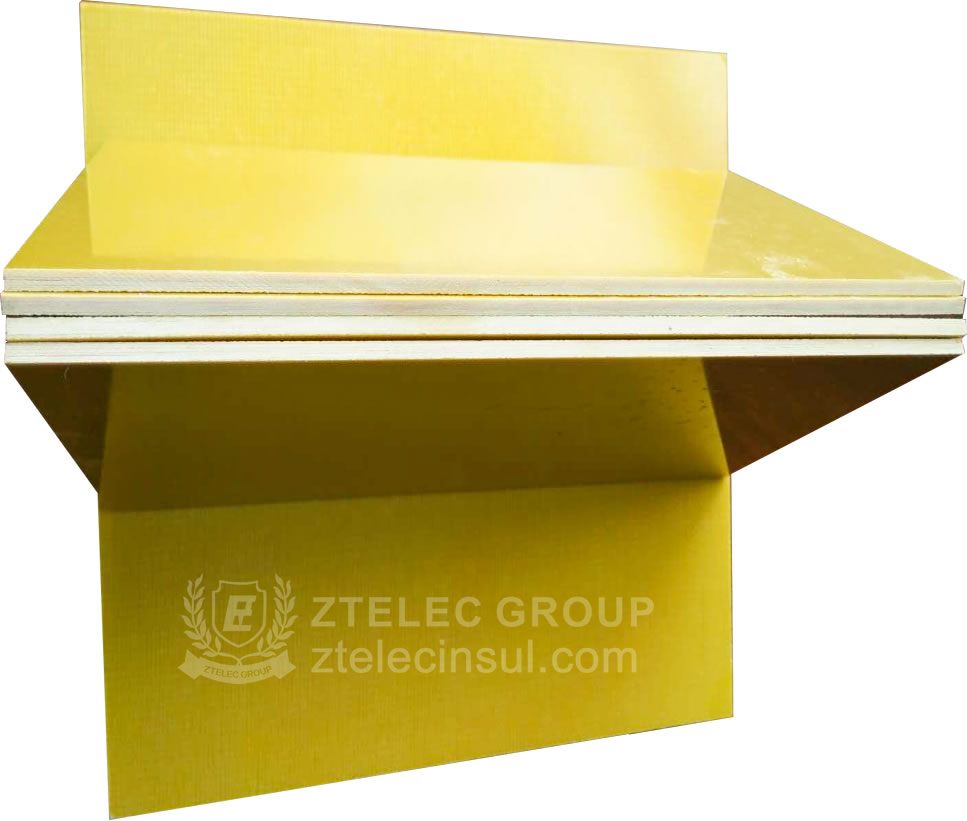

G-11 Fiberglass Sheet is a high-performance laminate made from glass cloth that has been impregnated with epoxy resin and then cured under high pressure and heat. It belongs to the NEMA G-series of laminates, known for their excellent mechanical strength, electrical insulating properties, and high-temperature resistance.

G-11 is a high temperature glass epoxy laminate, a fiberglass reinforced epoxy resin composite.G11 and G10 have the same characteristics, but the temperature resistance level of G11 epoxy board is higher

Material Composition:

Made from woven fiberglass fabric combined with a high-temperature epoxy resin.

The epoxy resin gives the sheet its insulating and mechanical properties.

High-Temperature Resistance:

Continuous Operating Temperature: Up to 180°C (356°F).

Retains mechanical properties and electrical insulation capabilities even at elevated temperatures.

Mechanical Strength:

Exhibits high flexural, compressive, and tensile strength.

Tough and durable, making it ideal for applications that require wear resistance and dimensional stability.

Electrical Insulation:

Excellent electrical insulating properties, especially at high temperatures.

Suitable for use in electrical systems and components like transformers, switchgear, and printed circuit boards.

Moisture Resistance:

G-11 is resistant to moisture absorption, making it a good choice for environments where humidity or moisture is a concern.

Electrical Insulation: Used in transformers, motors, switchgear, and as an insulating barrier in various electrical components.

Aerospace: Lightweight and strong, G-11 is used in aircraft parts that require high thermal and electrical insulation.

Automotive: Found in components exposed to high temperatures and in electrical insulation in automotive systems.

Industrial Machinery: Used as support and structural components in machines that operate under high-stress conditions.

PCB Manufacturing: G-11 is used as the base material in the manufacturing of printed circuit boards (PCBs), thanks to its insulating and high-heat resistance properties.

G-11 is similar to G-10 fiberglass sheet but has higher temperature resistance, making it more suitable for high-heat applications.

G-10 is commonly used for general purposes, while G-11 is preferred in more demanding thermal environments.

Overall, G-11 fiberglass sheets are valued for their strength, thermal stability, and electrical insulation capabilities, making them essential in electrical, mechanical, and industrial applications.

Phenolic resin: Prepare suitable phenolic resin.

Glass fiber: Select a specific type of glass fiber, such as alkali-free glass fiber.

Impregnate the glass fiber in phenolic resin to make it fully saturated.

Lay the impregnated glass fiber in layers and put it into a mold for pressing. This process is usually carried out at a certain temperature and pressure to ensure the curing of the resin.

Curing is carried out at a specific temperature to convert the resin into a strong thermosetting material.

After the mold is removed, let the finished product cool at room temperature.

The cured board is post-processed by cutting, grinding, drilling, etc. to achieve the required specifications and surface finish.

Quality inspection of the finished product, including mechanical strength, electrical insulation, etc., to ensure compliance with standards.

Qualified products are packaged and stored in a dry and ventilated environment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……