In the field of industrial materials, FR5 epoxy sheets stand out with their unique performance advantages and have become an indispensable basic material in many industries. From high temperature resistance, high strength to excellent electrical properties, it occupies an important position in global industrial applications with its all-round excellent performance.

FR5 epoxy sheets can work stably for a long time in a high temperature environment of 155°C. Compared with the temperature limit of 130°C of ordinary FR4 materials, it has obvious advantages. This characteristic enables it to easily cope with high temperature industrial environments and provide guarantee for the stable operation of equipment.

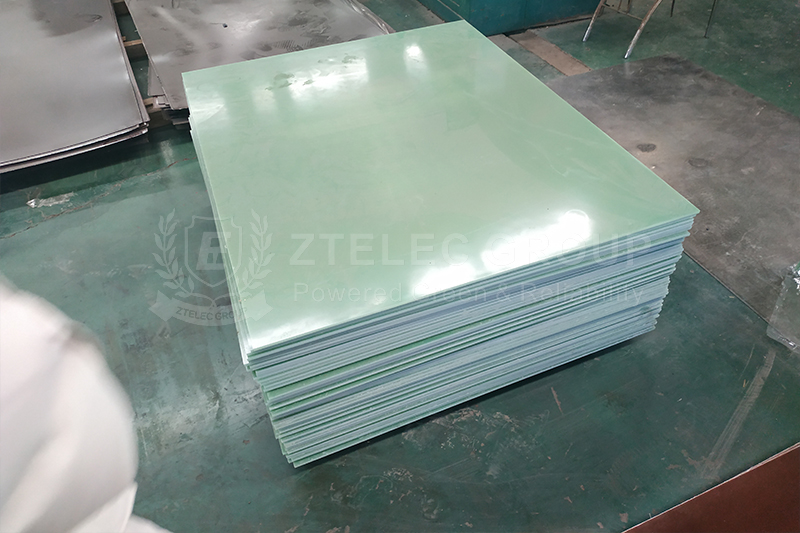

The FR5 epoxy sheet reinforced with high-density glass fiber not only has excellent bending strength but also good dimensional stability. In the face of severe mechanical stress, it can maintain structural integrity and is not easily deformed or damaged.

Low dielectric constant (Dk) and dielectric loss (Df) are significant advantages of FR5 epoxy sheets, making them an ideal choice for high-frequency electronic applications and able to meet the requirements of electronic devices for efficient signal transmission.

Whether it is acid-base corrosion or oil pollution erosion, FR5 epoxy sheets can show good tolerance. This strong environmental adaptability enables it to play a stable role in various harsh industrial environments.

In the global electronics industry, FR5 epoxy sheets are key materials for the manufacturing of printed circuit boards (PCBs). From consumer electronics products such as smartphones and tablets to industrial electronic devices such as industrial controllers and sensors, all rely on PCBs made of FR5 epoxy sheets. Its excellent electrical and mechanical properties ensure the stable signal transmission, reliable insulation and stable structure of electronic devices.

In the manufacturing process of electrical equipment, FR5 epoxy sheets are often used to make components such as insulation partitions, insulation pads and insulation sleeves. It can effectively isolate live parts, reduce the risks of electric leakage and short circuits, and ensure the safe operation of equipment. In high-voltage switchgear, FR5 epoxy sheets are even used to manufacture key components such as arc extinguishers. With its high temperature resistance and insulation properties, it can quickly extinguish the arc and protect the equipment from damage.

In automobile manufacturing, FR5 epoxy sheets are used to make the circuit boards of automotive electronic control units (ECUs) to ensure the stable transmission of electronic signals; in the battery management systems of new energy vehicles, it serves as an insulating component to improve battery safety. In the field of rail transit, it also plays an important role and is used to manufacture signal control equipment and electrical insulation components.

In addition to the above fields, FR5 epoxy sheets are also widely used in industries such as machinery manufacturing, medical equipment, and communication equipment. In machinery manufacturing, it is used to make components with requirements for insulation and mechanical properties; in medical equipment, it meets the equipment requirements with its good insulation and chemical stability; in communication equipment, it is used to manufacture high-frequency circuit boards to help with the rapid transmission of signals.

• Check the Certification Requirements: When purchasing FR5 epoxy sheets, it is necessary to pay attention to whether they have passed the UL certification and comply with the IEC standards. These authoritative certifications are important guarantees for product quality and safety.

• Evaluate the Strength of the Supplier: When evaluating the supplier, you can check whether it has the ISO certification and also examine its technical research and development strength. A high-quality supplier can not only provide products with reliable quality but also give guarantees in terms of technical support and after-sales service.

• Check the Performance Test Reports: Request performance test reports such as thermal stability and dielectric strength. Intuitively understand the product performance through the data to ensure that the selected FR5 epoxy sheet meets the actual application requirements.

• The development of 5G and the Internet of Things drives the growth of demand

• The outbreak of the new energy vehicle market brings new opportunities

• The research and development of environmentally friendly FR5 materials becomes the focus of the industry

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……