Insulation materials play a vital role in electronic and electrical equipment. They can prevent current leakage and ensure the normal operation of the equipment. FR4, FR5, G7, G10, and G11 are several representative insulation materials, each of which has unique performance characteristics. Understanding the differences between them will help you make a more appropriate choice in practical applications.

FR4 is a common composite material widely used in the manufacture of electronic circuit boards. It consists of a layer of glass fiber and a layer of epoxy resin. The glass fiber cloth, as a reinforcement material, provides good mechanical properties for FR4. Epoxy resin, as a matrix material, is bonded with the glass fiber cloth to form a strong composite material.

FR4 specifications:

Regular thickness: 0.5-50mm

Regular size: 1020×1220/1220×2040(mm)

Insulation grade: Class B

Color: The main colors are white (primary color), aqua, black and yellow.

The main characteristics and advantages of FR4: High mechanical properties, excellent electrical properties, good heat and moisture resistance, and good flame retardant performance.

Main Uses of FR4: FR4 insulation sheet is one of the main materials for making PCB boards (printed circuit boards). In electronic equipment, PCB boards carry a variety of electronic components and circuit connections, so their flame retardant properties are critical to the safety and stability of the equipment.

FR4 price: The price of FR4 per kilogram is about 8 yuan. But high-quality FR4 will definitely have a higher price. In addition, market supply and demand conditions and regional differences will also affect the price of FR4.

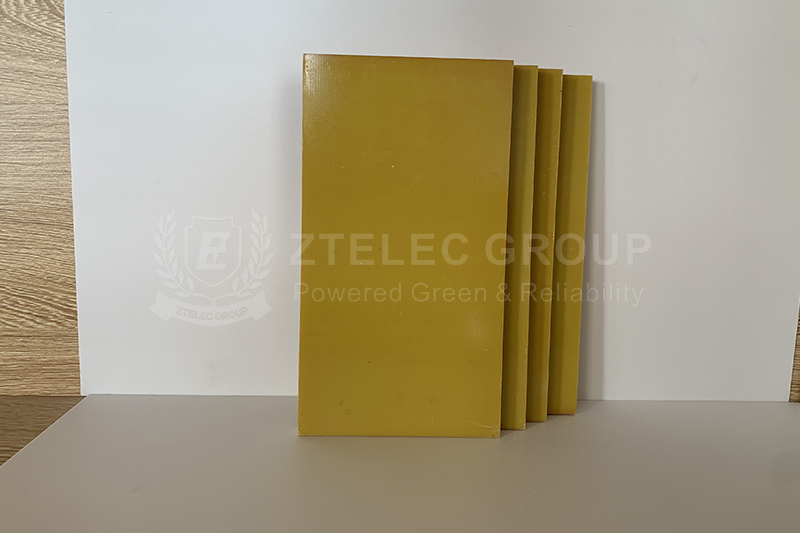

G11 is a hard cardboard-like insulating material made of imported electronic-grade alkali-free fiber glass cloth impregnated with imported epoxy resin, and added with corresponding imported flame retardants, adhesives, and other additives and processed by hot pressing. This material has high heat resistance, mechanical performance, and dielectric properties.

G11 specifications:

Regular thickness: 0.5-50 mm

Regular size: 1020 x 2040 mm x 1220/1220, 2800/3370, 1220 x 1400 x 2800 (support customize)

Insulation class: Class F

Colors: Yellow

Main features and advantages of G11: G11 has high mechanical properties, electrical properties, heat resistance, but also has excellent chemical resistance and processing properties.

Main Uses of G11: G11 is widely used in insulation components in motors, electrical equipment, as well as in aircraft, high-speed trains, transformer insulation boards, etc. It can also be used in humid environments and transformer oil, and is suitable for high-voltage switchgear, high-voltage switches, and other occasions.

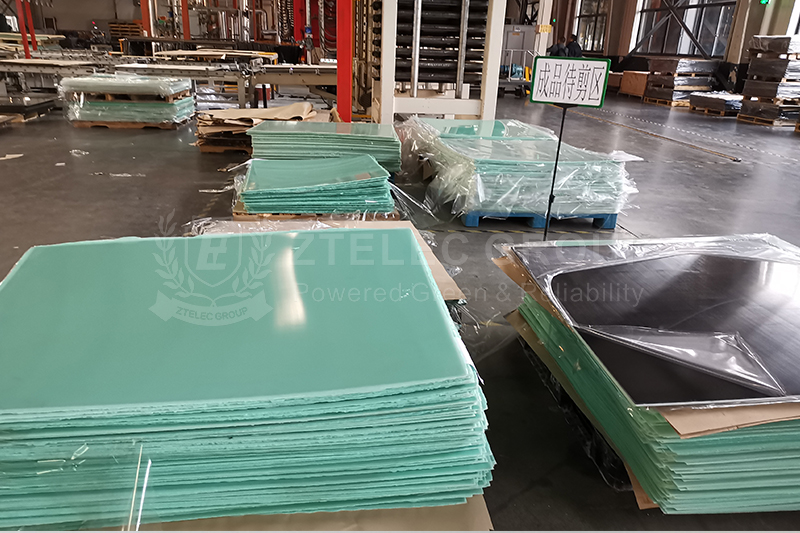

FR5 sheet (Flame Retardant Level 5) is a common fiber glass reinforced epoxy resin insulation material. It is made of epoxy resin and fiber glass cloth.

FR5 specifications:

Regular thickness: 0.5-50 mm

Regular size: 1020 x 2040 mm x 1220/1220(support customize)

Insulation class: Class F

Water absorption: Water absorption ≤0.09%.

Coefficient of thermal expansion: Coefficient of thermal expansion ≤6 x 10^-6 cm/cm°C.

Color: It is usually aqua green or aqua blue.

The main features and advantages of FR5: The features of FR5 are very similar to those of the FR4 and G10 mentioned above. In addition, FR5 also has good flame retardant properties. When the material is ignited, it can self-extinguish in a short time, thus effectively preventing the spread of the fire.

Main uses of FR5: FR5 is also widely used in motors and transformers. In addition, FR5 is also widely used in various electronic devices, such as PCB testing, insulation structural parts of electrical equipment, etc.

G7 is mainly made of treated alkali-free glass fiber cloth impregnated with a specific silicone resin, and then baked and dried and hot-pressed.

G7 specifications:

Regular thickness: 0.5-50mm

Regular size: 1020×2020mm (support customize)

Insulation level: Class C

Color: White

The main features and advantages of G7: G7 has high heat resistance, flame retardant, leakage resistance, as well as good arc resistance, dielectric strength and voltage resistance. In addition, it also has a low water absorption and stable size. It is suitable for applications with high mechanical strength and electrical properties.

The main use of G7: G7 is mainly used in various insulation partitions of high, medium and low voltage switchgear, as well as occasions requiring high mechanical strength and electrical performance.

G10 is a composite material made of fiber glass cloth and epoxy resin, originally developed for use in aircraft, and it is capable of withstanding great forces without deformation. This material has insulating and acid-alkali resistance properties, and is not permeable to water vapor or liquids, while being lightweight. These characteristics make G10 an ideal choice for various fields such as electronics, aerospace, chemical industry, and precision instrument manufacturing.

G10 specifications:

Regular thickness: 0.5-50mm

Regular size: 1020×1220/1220×2040mm, 1220×2800/3370,

1400×2800 (support customize)

Insulation grade: Class B

Color: Aqua, black, white

Performance and advantages of G10 sheet: Good flame retardancy, good insulation and heat resistance, excellent mechanical strength.

Main uses of G10 sheet: G10 sheet is used as insulating structural parts in motors and electrical equipment, such as circuit breakers, switchgears, transformers, DC motors, AC contactors, explosion-proof electrical appliances and other electrical appliances.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……