In the electronics manufacturing industry, PCB, as the basic skeleton of electronic equipment, carries the connection and communication tasks of various electronic components. As one of the most common substrate materials in PCB manufacturing, the importance of FR-4 material is self-evident. This article will discuss in depth the definition, characteristics, applications and advantages of FR-4 material.

1. Definition of FR-4 material

FR-4, full name Flame Retardant 4, is a glass fiber reinforced epoxy resin laminate material. The name does not refer to a specific material, but a general term for a class of materials with a specific fire rating and composition.

According to the classification standard of NEMA (National Electrical Manufacturers Association), FR means that the material has flame retardant properties, and the number “4” represents its specific composition: epoxy resin as an adhesive, electronic grade glass fiber cloth as a reinforcing material, and the flame retardant grade reaches UL94 V-0 standard.

2. Characteristics of FR-4 material

High mechanical strength: Glass fiber reinforcement gives FR-4 substrate excellent bending and impact resistance, and can withstand the stress caused by complex circuit layout.

Excellent electrical performance: FR-4 material has good electrical insulation performance, which can effectively prevent interference and short circuits between different circuits on the circuit board, and ensure the stability and reliability of signal transmission.

Good flame retardant performance: UL94 V-0 level flame retardant performance enables FR-4 material to quickly self-extinguish when encountering fire, greatly improving the safety of electronic products.

Good processing performance: FR-4 material is easy to drill, cut, bend and other processing operations, suitable for realizing complex multi-layer board structures.

Moderate cost: Compared with other high-performance materials, the manufacturing cost of FR-4 material is relatively low, suitable for large-scale production.

3. Application of FR-4 material

FR-4 material has been widely used in the field of PCB manufacturing due to its excellent comprehensive performance. Whether it is a single-layer, double-layer or multi-layer PCB, FR-4 is one of the preferred substrate materials. It is widely used in many fields such as computers, communication equipment, consumer electronics, medical equipment, industrial control systems, etc. Especially in multi-layer PCBs, FR-4 materials can meet the needs of highly complex circuit design, provide stable electrical performance and good heat dissipation.

4. Advantages of FR-4 Materials

Wide applicability: FR-4 materials are suitable for a variety of different circuit design requirements, from simple single-layer boards to complex multi-layer boards, and can provide stable and reliable performance.

Safety guarantee: Its flame retardant properties enable electronic products to quickly extinguish themselves when encountering a fire source, reducing the risk of fire and ensuring user safety.

Cost-effectiveness: The relatively moderate manufacturing cost makes FR-4 materials the preferred material in large-scale production, which helps to reduce the overall cost of electronic products.

Strong processability: Good processing performance enables FR-4 materials to easily cope with various complex processing technology requirements and improve production efficiency.

As one of the core substrate materials in PCB manufacturing, FR-4 materials occupy a pivotal position in the electronics manufacturing industry with their excellent mechanical strength, electrical properties, flame retardant properties, good processing performance and cost-effectiveness.

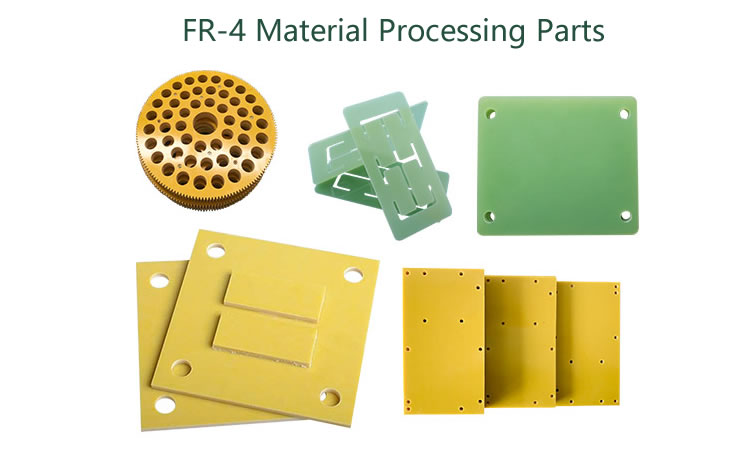

5. FR4 material processing parts

With the continuous development of electronic technology, FR-4 materials will continue to play an important role in promoting the performance improvement and cost reduction of electronic products. For SMT patch processing plants, in-depth understanding of the characteristics and applications of FR-4 materials is of great significance to improving product quality and production efficiency.

Ztelec Group is a professional manufacturer of high-quality electrical insulation materials with more than 60 years of manufacturing experience.

If you need more product information and quotes, please contact us.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……