FR4 epoxy sheet is made of alkali-free glass fiber cloth for electrical workers impregnated with epoxy phenolic resin, baked and hot-pressed. It has high mechanical and dielectric properties, the surface should be smooth, free of bubbles, wrinkles and cracks, good heat resistance and moisture resistance, and good machinability, and the heat resistance grade is Class B. It is suitable for use as insulating structural parts in motors and electrical equipment, and can be used in humid temperature environments and transformer oil. With high mechanical and electrical properties, it is widely used as insulating materials and components in generators, motors, and electronic equipment. It is also very suitable for transformer oil pressure and humidity environments.

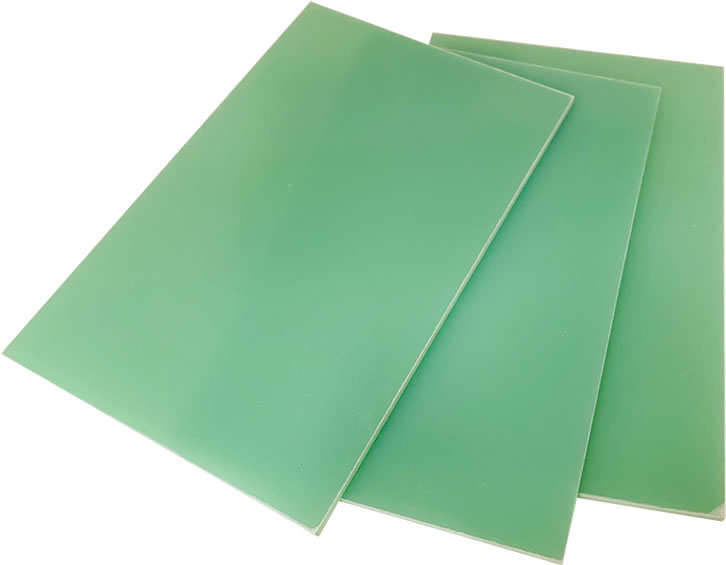

FR4 epoxy sheet, color is white, yellow, green, still has high mechanical strength at room temperature of 150℃, good electrical performance in dry and wet states, its vertical layer electrical strength: ≥14.2MV/m, is the choice of many insulating parts.

Easy to cure: choose a variety of different curing agents, the epoxy resin system can be cured almost in the temperature range of 0~180℃.

High temperature resistance: It can withstand high temperatures up to 140 degrees. In this way, there is no need to worry that the insulation performance of the material will be seriously damaged as the temperature rises.

Outstanding flame retardant performance: It is a good product of fr4 epoxy sheet. Its flame retardant performance meets the UL94V-0 standard. Simple processing procedures: Only high temperature and high pressure are required during the entire processing process. Convenient and fast. Good appearance: Its surface flatness is very good, without pits, and thickness tolerance standard. Wide thickness range: Its processing thickness ranges from 0.1mm to 100mm, giving people more choices.

The fr4 epoxy sheet processing has very excellent mechanical properties, excellent rigidity, as hard as steel, significant performance in toughness, and good elasticity. Of course, it can also withstand very strong impact. Another point is the anti-creep property, which is very outstanding in the stability of the material. Coupled with various forms, convenient curing, strong adhesion, and low shrinkage, epoxy sheets have a broad market in high-insulation structural parts for machinery, electrical appliances and electronics.

1.FR4 insulation board should not be placed in direct sunlight. Some friends want to take it out to bask in the sun because it has been stored in one place for a long time, so they may put it in direct sunlight, which is harmful to the performance characteristics of the epoxy sheet. It should be dried in a cool place.

2.Pay attention to the storage environment of FR4 epoxy sheet. Many friends put insulation boards in warehouses for a long time without paying attention to the dryness of the air and the humidity of the environment. The generally suitable environmental conditions are that the air humidity does not exceed 70% and the temperature is around 25℃.

3.Pay attention to the use limit of FR4 epoxy sheet. Generally, the temperature may exceed 160 degrees and may deform. Be sure to pay attention to the temperature when using it.

4.Pay attention to maintenance. Maintenance, literally means protection and maintenance, so maintenance is also very important.

To sum up, it is not difficult to see that in order to extend the service life of FR4 epoxy sheet, you need to pay more attention to the storage environment and do not store it at will, so as not to affect its performance. I believe that after doing a good job of maintenance, everyone can greatly extend its service life.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……