Phenolic sheet and bakelite sheet are both made from phenolic resin and paper through a process of heat and pressure. The main difference lies in the type of paper used, which determines their respective applications. In the following sections, we will delve into the characteristics, types, and Application of Phenolic sheet and bakelite sheet.

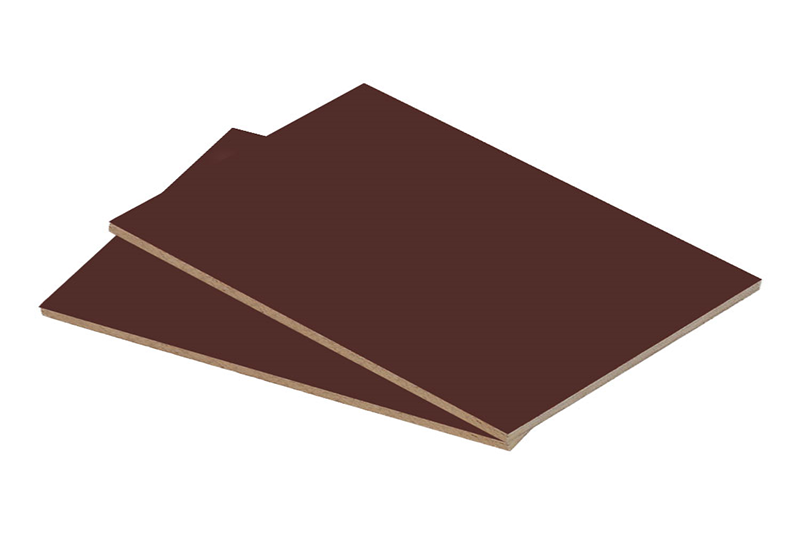

Phenolic sheet is a rigid and brittle thermosetting material made by layering phenolic resin and kraft paper through high-temperature compression. It exhibits strong mechanical and dielectric properties.

Phenolic sheet can be divided into two major categories:

Paper phenolic sheet is a thermosetting composite material. It is made by impregnating layers of paper with phenolic resin and then subjecting it to high temperature and pressure. This unique combination of material and manufacturing process creates a versatile and durable circuit board with excellent electrical, mechanical, and thermal performance.

Applications: Paper phenolic sheets are primarily used for gaskets, small parts, and oil-immersed transformers.

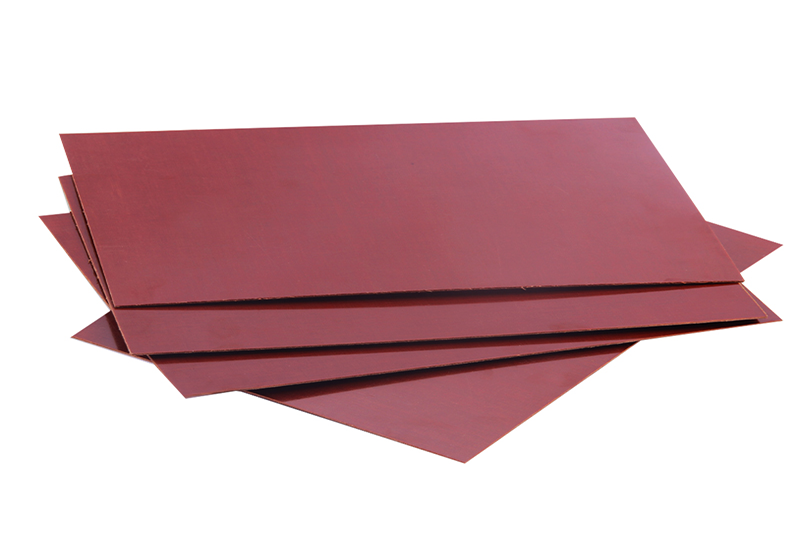

2.Cotton Cloth Phenolic sheet:

Cotton cloth Phenolic sheet is a thermosetting composite material made by impregnating cotton cloth with phenolic resin and then subjecting it to pressure and heat. This material is softer, wear-resistant, and has lubricating properties.

Applications: Cotton cloth Phenolic sheets are ideal for mechanical gears, pulleys, bearing protectors, motors, and electrical components that require excellent mechanical strength and electrical performance.

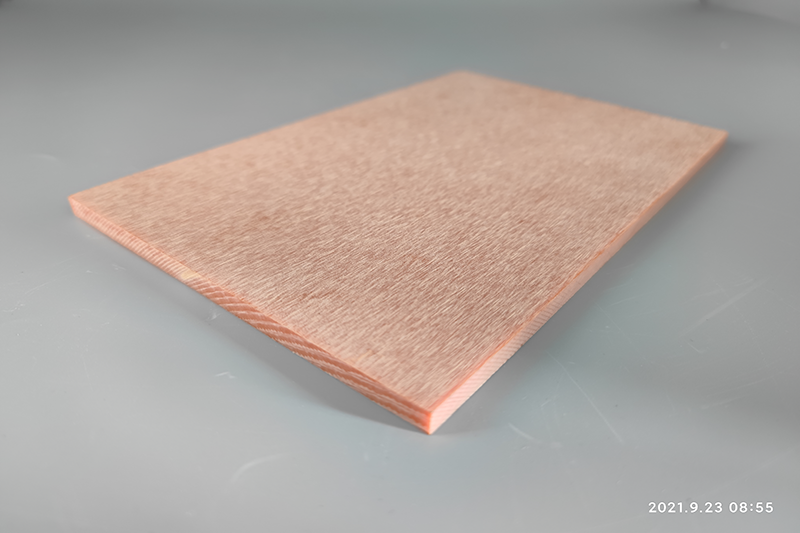

bakelite sheet is also a rigid and brittle thermosetting material. It is made by laminating insulating impregnated paper with phenolic resin, exhibiting high mechanical and dielectric properties, as well as excellent resistance to moisture, heat, and acids. It is classified as an E-class insulation material.

Due to the different materials used, bakelite sheets can be categorized into several types:

1.Fixture Plate:

Fixture plates, also known as bakelite sheet for fixture plates, are made by impregnating insulating paper with phenolic resin and then subjecting it to baking and hot pressing.

Applications: Fixture plates are widely used in the PCB industry for backing plates, distribution boxes, fixture plates, insulation boards for switch cabinets, and mold laminates.

2.Grinding Plate:

Grinding plates are produced by grinding the surface of bakelite sheet boards, which are made by subjecting bleached wood pulp paper impregnated with phenolic resin to heat and pressure. They have the characteristics of good flatness, uniform thickness, and a shiny surface.

Applications: Grinding plates are suitable for use in PCB drilling machines, forming machines, motor base support plates, testing base plates, and mechanical grinding tools.

3.Phenolic Backer:

Phenolic backers, also known as XPC boards, are made using low-temperature processes from insulating impregnated kraft paper core boards with phenolic resin. They exhibit excellent punching and shearing properties at room temperature, as well as good electrical performance and temperature resistance.

Applications: Phenolic backers are used in PCB punching machines, forming machines, testing base plates, and punching boards for high-end communication backplanes.

ESD bakelite sheet is an antistatic bakelite sheet board made by adding antistatic agents to the bakelite sheet material. It possesses stable antistatic properties, high mechanical strength, and excellent processability.

Applications: ESD bakelite sheet is suitable for use in PCB drilling backup boards, fixtures, distribution boards, mechanical parts, and test benches.

These are all the different types of Phenolic sheet and bakelite sheet. If you have any further questions about Phenolic sheet or bakelite sheet, please feel free to contact us for free technical consultation.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……