3240 epoxy sheet, as a material with unique properties, is constantly showing its infinite possibilities in various fields.

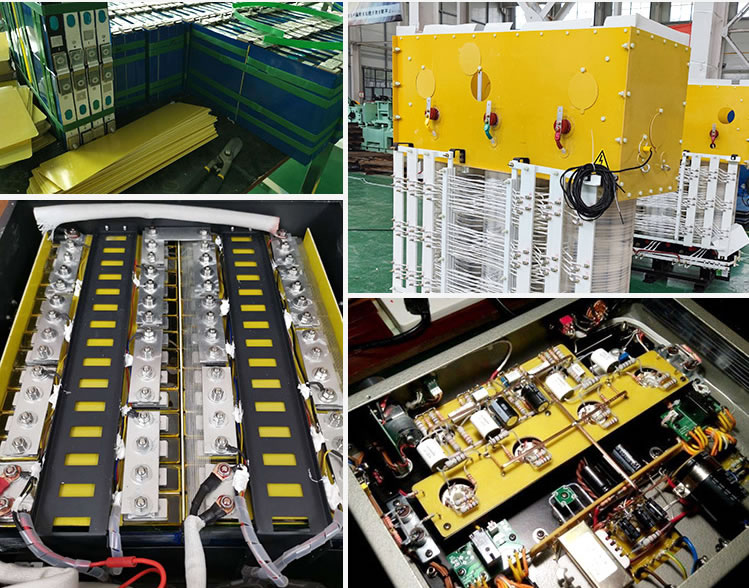

3240 epoxy sheet has become an ideal material for manufacturing printed circuit boards (PCBs) due to its excellent insulation properties and stable electrical parameters. In high-density and high-precision PCB manufacturing, 3240 epoxy sheet can provide reliable insulation support to ensure the normal operation of the circuit. At the same time, its low expansion coefficient can adapt to the heat changes generated by electronic components during operation, effectively avoiding circuit failures caused by thermal expansion and contraction.

Aerospace has extremely demanding requirements on the performance of materials. 3240 epoxy sheet has been used in aircraft structural parts, satellite components, etc. due to its light weight, high strength, high temperature resistance and radiation resistance. For example, the internal components of aircraft engines need to work under high temperature, high pressure and high vibration. 3240 epoxy sheet can meet the requirements of these extreme conditions and ensure flight safety.

In the field of rail transportation, 3240 epoxy sheet also plays an important role. The electrical system, traction system and other key parts of high-speed trains all require high-performance insulation materials to ensure the reliability and safety of operation. The wear and aging resistance of 3240 epoxy sheet enables it to maintain good performance in long-term operation, reducing maintenance costs and downtime.

In the field of new energy, such as the manufacture of solar photovoltaic panels, 3240 epoxy sheet can be used as a backboard material to provide good insulation and protection, extending the service life of photovoltaic panels. In the manufacture of wind power blades, it can also be used to enhance the structural strength and weather resistance of blades.

With the continuous development and innovation of science and technology, the performance of 3240 epoxy sheet is still being optimized and improved, and its application field will continue to expand, creating more possibilities for human scientific and technological progress and industrial development.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 60 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first.

If you need to know more about Diamond Dotted Paper and other insulation materials product information and quotations, please contact us, we can mail you samples for your testing.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……