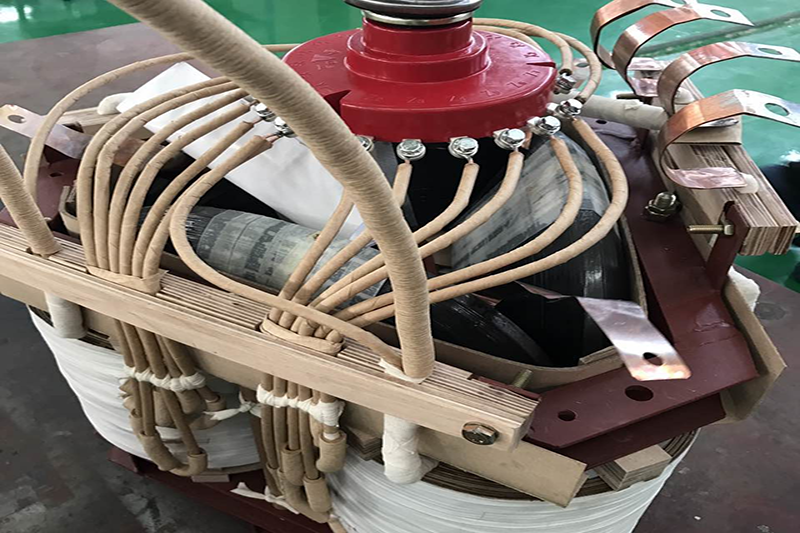

Overview: Crepe paper is mainly made from insulating kraft paper processed by creping, and it has excellent oil solubility. It is widely used in the insulation of oil-immersed transformers, reactors, and other components, especially as insulation for lead components, in order to improve the electrical insulation and mechanical performance of the product structure.

Product features:

1.Insulation class A (105℃)

2.Colors: natural brown, beige

3.High purity and oil absorption capacity

4.Good dielectric strength

5.Good compatibility with insulating liquids (mineral oil, silicone oil, askarel)

6.Does not contain conductive particles

7.For more detailed product parameters, please click on the Crepe Paper details page.

Overview:Crepe paper tubes are made from electrically insulating paper tubes processed by special techniques. The raw materials are the same as crepe paper, but the shape is different to meet different application needs.

Product features:

1.Insulation class A (105℃)

2.Colors: natural brown, beige

3.The crepe direction is horizontal.

4.Can be bent in any direction without breaking

5.Good compatibility with insulating liquids

6.For more detailed product parameters, please click on the Crepe Paper Tube details page.

1.Iulation performance:

Both crepe paper and crepe paper tubes have good insulation properties. This means that they can effectively isolate current, prevent the risk of electric shock, and provide electrical insulation protection.

2.Cable insulation applications:

Both crepe paper and crepe paper tubes are commonly used in cable insulation applications. They can be used as insulation layers to protect the conductors inside cables from the influence of external environments and ensure the normal operation of the cables.

3.Physical protection:

Both crepe paper and crepe paper tubes can provide physical protection. They can prevent cables or insulation materials from being subjected to external pressure, abrasion, or damage, and increase the durability and service life of the cables.

4.Plasticity:

Both crepe paper and crepe paper tubes have plasticity and can be flexibly bent and shaped according to needs to adapt to the shape and size of different cables or insulation components.

1.Different shapes:

Crepe paper exists in the form of paper, with creases and longitudinal stretch properties. Crepe paper tubes are made by rolling crepe paper into a tube shape, forming a hollow cylinder.

2.Different application scopes:

Crepe paper is mainly used in electrical insulation, cable insulation packaging, and other fields. It can be used as an insulation layer to isolate current and prevent the risk of electric shock. Crepe paper tubes are usually used in cable insulation protection, wire harness packaging, insulation filling, and other applications, providing additional physical protection and insulation performance.

3.Different physical characteristics:

Crepe paper usually has higher insulation performance, effectively preventing the flow of current. It also has a certain degree of flexibility and abrasion resistance. Crepe paper tubes inherit the insulation performance of crepe paper and, due to their tubular structure, have certain strength and compression resistance.

4.Different dimensions and specifications:

The dimensions of crepe paper can be customized according to needs and are usually provided in the form of paper. The dimensions of crepe paper tubes usually cover aspects such as diameter, wall thickness, and length to meet different application needs.

1.Variable shape: Crepe paper products are suitable for insulating irregular shapes and surfaces inside transformers.

2.Low cost: Compared to crepe paper tubes, crepe paper usually has a lower price and is more cost-effective.

1.Low mechanical strength: Crepe paper has relatively low mechanical strength and may not withstand high voltage, tension, or impact loads, requiring additional physical protection measures.

1.Higher mechanical strength: Crepe paper tubes have higher mechanical strength compared to crepe paper, providing better physical protection to prevent cables or insulation materials from being subjected to external pressure, abrasion, or damage.

1.Limited size and shape: The size and shape of crepe paper tubes are limited and may not be suitable for some special shapes or sizes of cables or insulation components.

2.Higher cost: Crepe paper tubes usually have a higher price and higher cost compared to crepe paper.

crepe paper and crepe paper tubes each have their own advantages and disadvantages. In specific applications, evaluation and selection should be based on actual needs and requirements. If you have any professional technical questions, you can contact us, and our professional technicians will answer them for you.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……