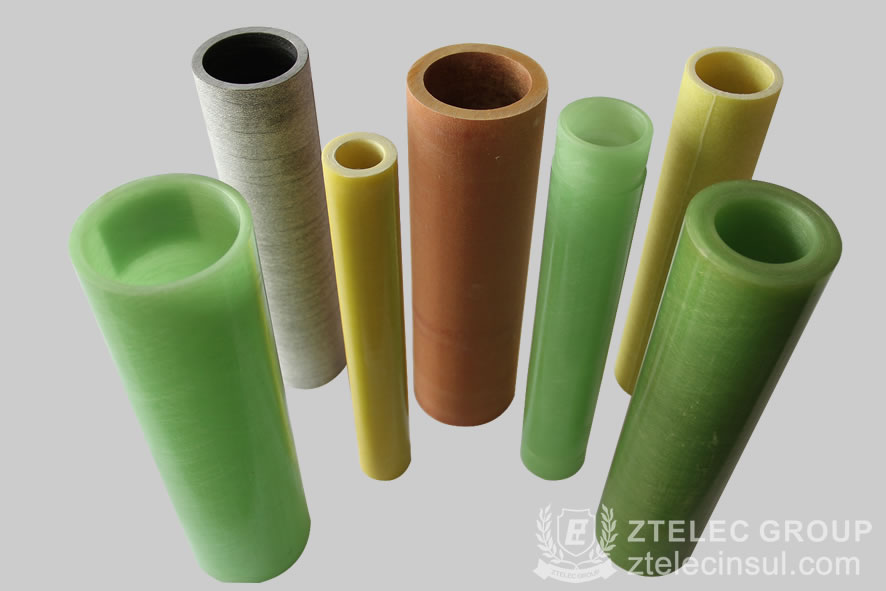

Epoxy fiberglass winding tube is a high-performance insulating material, which is made by impregnating electrical-grade alkali-free glass fiber filaments with resin and then winding them under microcomputer control.

High strength, high rigidity: It can withstand large internal and external pressure and is suitable for high pressure conditions.

High temperature resistance: It has good thermal stability and can be used in high temperature environment for a long time. High temperature resistance grade is usually B (155℃), and some high-performance products can reach 180℃.

Corrosion resistance: It can resist all kinds of acid, alkali, salt and other corrosive media erosion and extend the service life.

Good insulation performance: It belongs to the insulation material. Parallel layer to the breakdown voltage is high. It can be used in high-power electrical appliances.

Light weight, easy installation: light weight, less connectors, no need for large equipment, easy installation and laying.

Energy saving and environmental protection: It has low energy consumption and carbon emissions, which is in line with the concept of green environmental protection.

Strong plasticity: The processing methods are various. It can be cut, grinding, drilling. It can be manufactured according to drawings into the required style.

Power industry

Cable protection: Epoxy fiberglass winding tube can be used as a protective sleeve of the cable to prevent the cable from being damaged by the external environment, while improving the insulation performance of the cable.

Transformers and reactors: In the manufacture of transformers, reactors and other equipment, epoxy fiberglass winding tubes can be used to make fuel tanks, coils and other components to improve the insulation performance and high temperature resistance of the equipment.

Oil and gas industry

Transmission pipeline: Epoxy fiberglass winding tubes can be used as oil, natural gas and other media transmission pipeline, especially in the need to withstand high pressure and corrosive media occasions.

Storage tanks and equipment: In the manufacture of storage tanks, reactors and other equipment, epoxy fiberglass winding tubes can be used to strengthen the structure, improve corrosion resistance and high temperature resistance.

Chemical industry

Corrosive media transportation: Because the epoxy fiberglass winding tube has excellent corrosion resistance, it is especially suitable for transporting various corrosive chemical media, such as acid, alkali, salt, etc.

Chemical reactors: In chemical reactors, epoxy fiberglass winding tubes can be used to make stirrers, pipes and other components to improve the corrosion resistance and service life of the equipment.

Marine and Ocean Engineering

Seawater piping system: Epoxy fiberglass winding tube can be used to make seawater piping system in Marine and Marine engineering to prevent seawater corrosion of pipelines.

Fuel system: In the fuel system, epoxy fiberglass winding tube can be used to make components such as fuel lines and fuel tanks to improve the corrosion resistance and high temperature resistance of the system.

Impregnation: Impregnate the fiberglass wire in an ultra-low viscosity high-temperature epoxy resin to ensure that the resin fully infiltrates the fiber.

Winding: Under the control of microcomputer, the impregnated fiberglass is cross-wound on the mold according to the predetermined angle and number of layers.

Curing: After a certain temperature and time, the epoxy resin is cured to form a pipeline with certain strength and rigidity.

Epoxy fiberglass winding tube not only has unique performance advantages and widely used in various fields, but also plays a positive role in promoting the development of related industries. Therefore, we should pay more attention to the research and application of epoxy fiberglass winding tubes, and make greater contributions to the development of related industries and the progress of society.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……