Epoxy Fiberglass Rod, referred to as epoxy glass cloth laminated rod or epoxy rod, is a high-performance composite material product. The following is a detailed introduction to the product:

Epoxy resin glass fiber laminated rod is a rod with a round cross-section made of alkali-free glass cloth for electricians impregnated with epoxy resin and then hot-pressed by a molding mold. Its manufacturing process includes multiple steps such as impregnation, baking, hot pressing and molding to ensure that the product has excellent performance.

Excellent insulation performance: Epoxy resin glass fiber laminated rod has high dielectric properties and can be used as an insulating structural component in electrical equipment to ensure the safe operation of the equipment.

Good mechanical properties: The product has high mechanical strength, including bending strength, compressive strength and shear strength, and can withstand greater mechanical stress.

Corrosion resistance: Epoxy resin glass fiber laminated rod has good resistance to the atmosphere, water and general concentrations of acids, alkalis, salts, and various oils and solvents, and can be used for a long time in harsh environments.

Dimensional stability: The product has stable dimensions and is not easily deformed, and can meet various precision processing and assembly requirements.

Processability: Epoxy resin fiberglass laminated rods can be processed mechanically to meet production needs, including cutting, drilling, grinding, etc., and have high processability.

The dimensions of epoxy resin fiberglass laminated rods can be customized according to specific application requirements and the production capacity of the manufacturer. Generally speaking, the diameter of such laminated rods can range from a few millimeters to hundreds of millimeters, and the length can be cut as needed.

In the market, common epoxy resin fiberglass laminated rod diameter specifications include 8mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm 50cm 65cm 100cm, etc., and the length is usually 1 meter or customized according to customer needs. In addition, some special specifications of laminated rods, such as products with larger diameters or longer lengths, can also be obtained through special customization.

The colors of epoxy resin fiberglass rods usually include a variety of options to meet the needs of different fields and applications. The following are some common epoxy fiberglass rod colors and their characteristics:

Aqua: Aqua is a common color in epoxy fiberglass rods, usually used in electrical insulation, line fixing and other fields. This color of epoxy fiberglass rod has good insulation and high temperature resistance, so it is widely used in the electrical industry.

Yellow: Yellow epoxy fiberglass rods are usually used in products that require high strength and corrosion resistance, such as blades in wind and hydropower generation. Yellow fiberglass rods also have high mechanical strength and wear resistance, and are suitable for some occasions with high material performance requirements.

Black: Black epoxy fiberglass rods are also common in some specific applications, such as occasions that need to hide or reduce light reflection. Black fiberglass rods usually have good light absorption and weather resistance, and are suitable for some outdoor environments or environments that require long-term exposure to sunlight.

White: Although white epoxy fiberglass rods are not as common as aqua and yellow, they are also used in some occasions that require high transparency and good appearance. White fiberglass rods usually have good corrosion resistance and mechanical strength, and are suitable for some occasions that have certain requirements for material performance.

Electrical equipment: used for insulating structural parts in motors and electrical equipment, such as insulators, insulating partitions, etc.

Machinery manufacturing: used to manufacture mechanical parts that require wear resistance, corrosion resistance, and high strength, such as bearings, gears, etc.

Chemical industry: used to manufacture pipes, valves, pumps and other products, which can be used for a long time in environments with severe chemical corrosion.

Aerospace: used to manufacture structural parts and parts of aircraft, rockets and other aerospace vehicles, meeting the requirements of lightweight, high strength and corrosion resistance.

Property Parameter of Epoxy Resin Fiberglass Cloth Laminated Rod (refer to 3840 EPGC41)

Executive Standard:GB-T 5132.1-2009 IEC61212-1:2006

| Number | Item | Unit | Value |

| 1 | Density | g/cm3 | 1.7-1.8 |

| 2 | Flexural Strength at Perpendicular Lamination(Under Normal) | MPa | ≥220 |

| 3 | Axial Compressive Strength | MPa | ≥175 |

| 4 | Breakdown Voltage at Parallel Lamination(Transformer Oil at 90℃) | Kv | ≥40 |

| 5 | Insulation Resistance after Immersion | MΩ | ≥1000 |

| 6 | Dielectric Loss Factor(50Hz) | – | ≤0.03 |

| 7 | Water Absorption | Mg/cm2 | ≤3 |

| 8 | Thermal Index | – | 155 |

Understand product specifications: Choose the appropriate product specifications and length according to your needs to ensure that the use requirements are met.

Compare prices and quality: During the purchase process, comprehensively compare the prices and qualities of different products and choose products with higher cost performance.

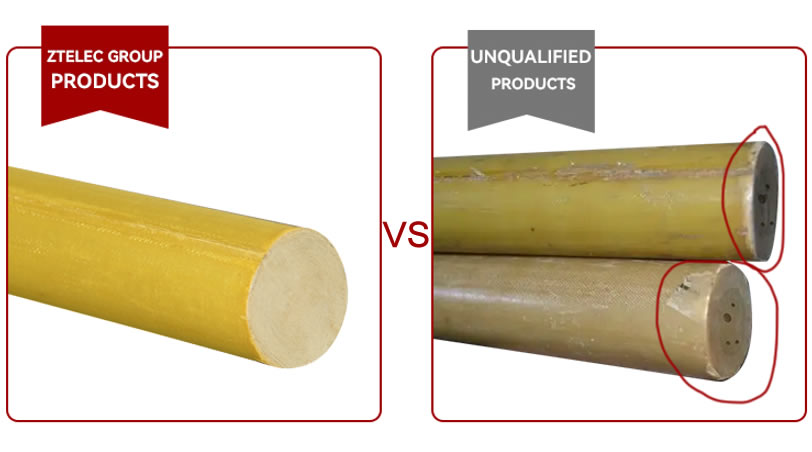

Choose well-known brands: When purchasing, give priority to well-known brands and reputable manufacturers to ensure product quality and after-sales service.

Pay attention to transportation and storage: During transportation and storage, pay attention to moisture-proof, sun-proof and avoid mechanical damage to ensure product performance and service life.

In summary, epoxy resin glass fiber laminated rod is a high-performance composite material product with excellent insulation performance, mechanical properties, corrosion resistance and processability, and is widely used in electrical equipment, machinery manufacturing, chemical industry, aerospace and other fields. When purchasing, it is recommended to choose according to your needs and actual situation to ensure that the quality and performance of the product meet the requirements.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 60 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first. Products are exported to Europe, America, Southeast Asia and other countries and regions.

If you need to know more about epoxy fiberglass laminated rods and other insulation materials product information and quotations

please contact us, we can mail you samples for your testing!

Welcome to visit our factory for guidance.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……