Selecting the right insulation materials for electric motors is vital to ensure their safe and reliable operation. Motor insulation materials provide electrical insulation and protection to various motor components, preventing electrical leakage, short circuits, and damage caused by heat, moisture, and contaminants. This article will discuss the different types of motor insulation materials and provide essential tips for choosing the right insulation for optimal motor performance.

Motor insulation materials are specially designed materials used to provide electrical insulation and protection for the various components of an electric motor. These materials are chosen for their high dielectric strength, thermal resistance, and mechanical durability. Common motor insulation materials include varnishes, resins, enamels, tapes, and coatings. These materials are applied to the motor windings, stator, rotor, and other components to prevent electrical leakage, short circuits, and damage caused by heat, moisture, and contaminants. Proper motor insulation is crucial for ensuring the safe and reliable operation of electric motors in various applications, from household appliances to industrial machinery.

There are several types of motor insulation materials used in electric motors. Here are some commonly used types:

These tapes, such as mica tape or fiberglass tape, are used to wrap and insulate motor windings. They provide mechanical strength and resistance against electrical and thermal stresses.

Papers made from materials like aramid or polyester are used as slot liners and interlayer insulation in motor windings. Insulation papers play a vital role in electric motors by providing electrical insulation and mechanical support to the motor windings. These papers are typically used as slot liners and interlayer insulation in motor windings.

Insulation films play a crucial role in electric motors by providing electrical insulation between motor windings. These films, typically made from materials like polyester or polyimide, offer excellent dielectric properties, high thermal stability, and mechanical strength. They are used to separate and insulate different layers of motor windings, preventing electrical leakage and short circuits. Insulation films also help to dissipate heat generated during motor operation and protect the windings from external contaminants. They are essential for ensuring the safe and reliable operation of electric motors by maintaining proper insulation and thermal management.

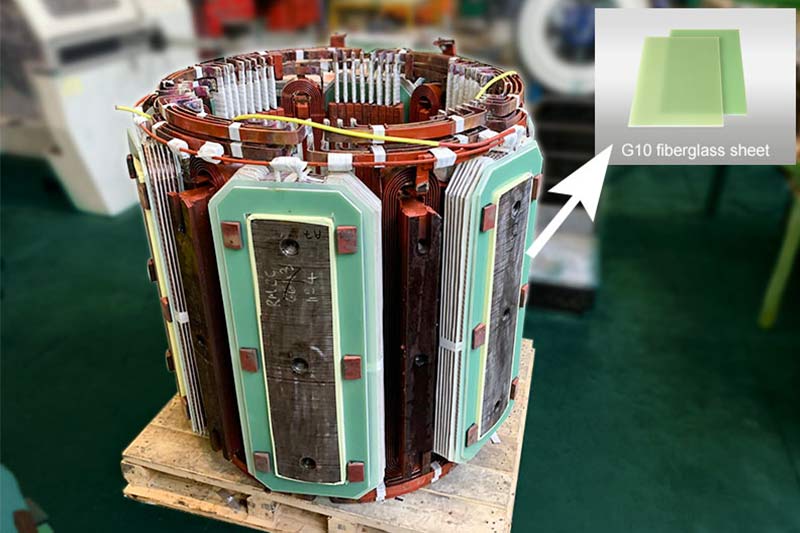

There are many different products of insulating sheets used in transformers. I will introduce them in detail to you.Mainly include:EPGC201/202/203/306、DPOGC301、 BMIGC301、PAIGC301、3241 Semiconductor laminated glass cloth board, magnetic conductive laminated glass cloth board.

The seven products, EPGC201/202/203/306, DPOGC301, BMIGC301, and PAIGC301, are all laminated products made from electrical (electronic) grade alkali-free glass fiber cloth impregnated with different types of resins and cured through heat pressing. They have temperature resistance ranging from class B (130℃) to class C (220℃) and exhibit excellent dielectric and mechanical properties. These products are widely used in high and medium voltage large motors with insulation classes of B/F/H. They can be processed into insulation structural parts for installation in various motors and electrical equipment, or fabricated into standard and non-standard parts such as slot wedges, pads, and strips.

3241 Semiconductor Laminated Glass Cloth Board: This laminated product is made from electrical-grade alkali-free glass fiber cloth impregnated with epoxy phenolic resin and added conductive components, cured through heat pressing. It exhibits semiconductor properties and is suitable for use as anti-tracking material in the slots of large high-voltage motors.

Magnetic conductive laminated glass cloth board:Laminated products made from electrical-grade alkali-free glass fiber cloth impregnated with insulating resin and added magnetic permeability components, cured through heat pressing. They are mainly used for processing into magnetic slot wedges for motors, which effectively connect the magnetic circuit inside the stator, improve the electromagnetic performance of motor slots, increase motor efficiency, reduce motor losses and temperature rise, and minimize motor-generated noise. This product features high magnetic permeability, high mechanical strength, excellent heat resistance, and ease of processing.

Insulation sleeves are integral components in electric motors, serving the crucial purpose of providing electrical insulation and protection for the wires and connections. These sleeves, typically made from materials like silicone or rubber, are used to cover and isolate the conductive elements within the motor, preventing electrical leakage and short circuits. Insulation sleeves offer excellent dielectric properties, flexibility, and resistance to moisture and contaminants. By effectively insulating the wires and connections, they ensure the safe and reliable operation of the motor. Insulation sleeves also provide mechanical protection, shielding the wires from physical damage and reducing the risk of insulation degradation.

Selecting the right insulation materials for electric motors is crucial for ensuring their safe and reliable operation. Here are some important considerations to keep in mind when choosing motor insulation materials:

Determine the temperature rating requirements of the motor and select insulation materials that can withstand the expected operating temperatures. Different grades of insulation material apply to different temperature grade requirements, taking into account factors such as hot spots, ambient temperature and thermal cycling to ensure the insulation material can withstand the heat without degrading.

Insulation materials should have high dielectric strength to withstand the electrical voltages and prevent electrical breakdowns. Consider the voltage levels the motor will be exposed to and choose materials with appropriate dielectric properties.

Motor insulation materials should possess sufficient mechanical strength to withstand mechanical stresses, vibrations, and thermal expansion. Evaluate the motor’s application and choose materials that can withstand the mechanical demands of the environment.

Ensure that the selected insulation materials are compatible with other components in the motor, such as adhesives, varnishes, and impregnation resins. Incompatible materials can lead to delamination, reduced insulation effectiveness, and compromised motor performance.

Evaluate the cost-effectiveness of the insulation materials. Balance the performance requirements with the budget constraints to select materials that offer the desired level of insulation performance at a reasonable cost.

Choosing the appropriate motor insulation materials is paramount for maintaining the integrity and efficiency of electric motors. Factors such as temperature rating, dielectric strength, mechanical durability, compatibility, and cost-effectiveness must be carefully considered during the selection process. By understanding the specific requirements of the motor and selecting high-quality insulation materials, motor performance can be optimized, ensuring safe and reliable operation in various applications. Remember, proper motor insulation is a critical investment that guarantees peak performance and extends the lifespan of electric motors.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……