There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

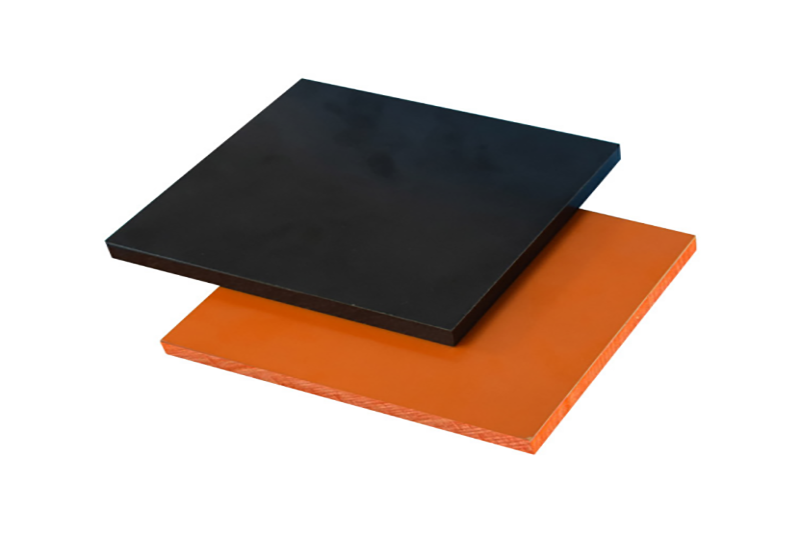

Summary: Bakelite, also known as phenolic laminate board, is made from high-purity phenolic resin and wood boards bonded with resin adhesive.

Dimensions: 1030*2030mm

Standard Thickness: 3-50mm

Colors: Orange, Black, Yellow

Email:[email protected] Whatsapp:+8613137718313

Bakelite, also known as Bakelite board, Bakelite sheet, Norplex board, Micarta board, phenolic board, Phenolic board, laminated board, and SRBF (Synthetic Resin Bonded Fabric), is a dense material. It is made by applying heat and pressure to layers of cellulose paper or fabric impregnated with synthetic resin (phenolic resin). During the application of heat and pressure, a polymerization reaction converts the layers into a thermosetting industrial laminate board. Phenolic laminate boards have extremely high durability, not only for electrical performance but also for heat and chemical resistance. Therefore, they are particularly suitable for emerging electrical and automotive industries.

1.Excellent Insulation:

Bakelite sheet are made of insulating materials and have excellent electrical insulation properties, effectively preventing the flow of electric current and providing reliable electrical insulation protection.

2.Water Resistance:

Bakelite sheet are non-absorbent and can maintain their insulation performance stability even in humid environments, reducing the impact of water on insulation materials.

3.High Temperature Resistance:

Bakelite sheet have excellent high temperature resistance and can work for a long time in high temperature environments without deformation or softening. This makes them suitable for electrical insulation applications under high temperature conditions.

4.Excellent Chemical Resistance:

Bakelite sheet can resist a certain degree of chemical corrosion and have good corrosion resistance. They can resist the erosion of certain chemicals, maintain stable insulation performance, and prolong service life.

5.High Mechanical Strength:

Bakelite sheet good mechanical strength and can withstand certain pressure and tension, providing reliable physical protection. They can prevent insulation materials from being damaged by external forces and ensure the normal operation of equipment.

6.Good Wear Resistance:

Bakelite sheet have a certain degree of wear resistance and can resist a certain level of abrasion. This allows them to maintain good insulation performance and mechanical strength in situations where frequent movement, contact, or friction occurs.

| ICT Fixtures | ITE Fixtures | Test Fixtures |

| Silicone Rubber Key | Fixture Plates | Table Grinding Plates |

| Packaging Machines | Combs | PCB Drilling Machine |

| main feature: | ||

| Density | G/Cm3 | 1.35-1.45 |

| Flammability | UL94 | HB |

| Water Absorption(5mm) | % | ≤2 |

| Chemical Family | Resin | Phenolic |

| Reinforcement Type | Paper | Kraft |

| Thermal Charactersitices | ℃ | 120(A) |

| Colour | Orange、Black | |

| Mechanical behavior: | ||

| FLEXURAL STRENGTH (23°C±2)⊥ | MPa | ≥ 120 |

| FLEXURAL MODULUS ⊥ | MPa | ≥ 7000 |

| TENSILE STRENGTH(LENGTHWISE) | MPa | ≥ 100 |

| Compressive Strength ⊥ | MPa | ≥ 150 |

| BONDING STRENGTH | N | ≥ 3000 |

| Electrical properties: | ||

| Electrical Strength ⊥ | Kv | ≥10 |

| INSULATION RESISTANCE | Ω | ≥5.0×10^7 |

| ARC RESISTANCE | Pti | ≥100 |

Q1: How should bakelite be stored?

A:To avoid rain and sunlight, the storage location should be indoors with relatively low temperature and dry conditions. The darkening of the color due to long-term storage is a chemical characteristic of the product and is considered normal. Poor storage conditions can cause rapid deterioration of product quality. For example, sunlight exposure can cause discoloration, and high temperature and high humidity storage environments can lead to degradation of electrical performance and flat bending or twisting deformation. When stored for a long time, the boards should be placed horizontally on a moisture-proof and flat carrier, and moisture should be blocked with moisture-proof materials.

Q2: Is bakelite toxic?

A:Bakelite sheet are non-toxic products and do not produce toxic substances. However, as a thermosetting plastic and phenolic plastic, phenolic laminate boards may release formaldehyde during the heating process, and formaldehyde is a toxic substance.

Q3: What is the lifespan of bakelite?

A:The lifespan of bakelite sheet can vary. Generally, the lifespan is around 3 to 5 years.

If you need our products please write down any questions, we will reply as soon as possible.