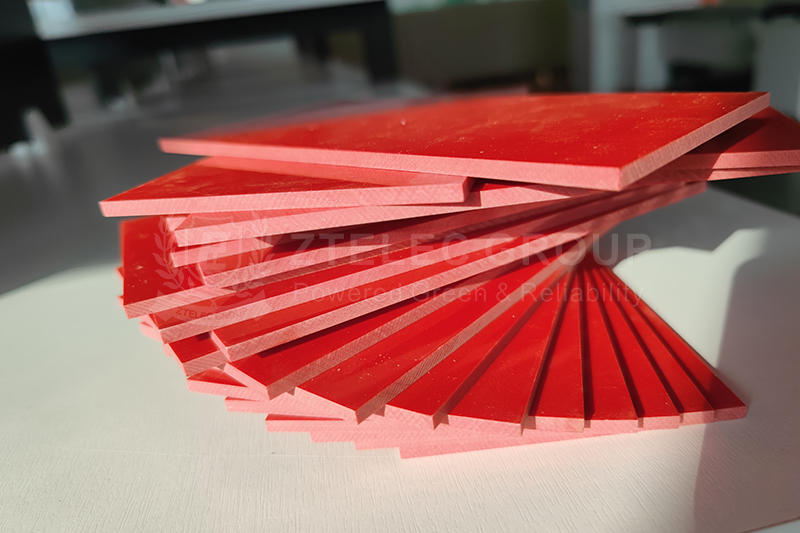

Bakelite sheet, also known as phenolic laminated paperboard, is a synthetic paperboard widely used in the industrial field. Although the name contains “wooden board”, it is not actually made of natural wood. It is an insulating material made of high-quality bleached wood building blocks and cotton linter paper as reinforcements, and phenolic resin made from high-purity, fully synthetic petrochemical raw materials as a resin binder. Bakelite sheet has a hard surface, is brittle and easy to break. It can make a wooden sound when knocked, is mostly opaque and dark in color, and does not soften in hot water.

The main component of bakelite sheet is phenolic resin, which gives it a variety of excellent physical and chemical properties. For example, it has extremely high insulation performance, does not absorb water, does not conduct electricity, and can maintain a stable working state in various electrical environments. In addition, bakelite sheet also has good wear resistance, high temperature resistance and corrosion resistance, and can be used for a long time in harsh working environments without being easily damaged.

Raw material preparation: First, high-quality bleached wood and cotton linter paper are prepared as reinforcements, and high-purity, fully synthetic petrochemical raw materials are used as raw materials for phenolic resin. The selection of these raw materials is crucial to the final performance of the bakelite sheet.

Phenolic resin synthesis: Phenol and formaldehyde undergo polycondensation under the action of a catalyst to produce liquid or solid phenolic resin.

Impregnation and drying: Bleached wood and cotton linter paper are impregnated in phenolic resin to fully absorb the resin. Then, the impregnated paper is dried to remove excess moisture and solvent.

Compression molding: The mixed resin and filler are placed in a mold and molded under high temperature and pressure. The material undergoes a curing reaction and finally forms a solid laminate.

Post-processing: The cured laminate also needs to be cut, drilled or surface-treated as needed to meet the needs of different applications.

Because bakelite sheet has many excellent properties, for example:

1. Bakelite sheet has high high temperature resistance and can withstand high temperatures of 150°C.

2. Bakelite sheet has good fire resistance and can produce no toxic gas after burning.

3. Bakelite sheet has good corrosion resistance and can prevent chemical substances from damaging it.

4. Bakelite sheet is a material with good insulation properties and is usually used as an insulating material for power equipment.

Bakelite sheet is widely used in many fields due to its excellent performance. In the electrical field, Bakelite sheet is often used to make insulating parts such as switches, sockets, and transformer housings; in the mechanical field, it can be used as parts such as gears and bushings.

As an excellent insulating material and base material for mechanical parts, bakelite sheet plays a pivotal role in the industrial field. Its unique manufacturing process and various excellent properties make it widely used in the electrical and mechanical fields. With the continuous advancement of science and technology and the continuous development of industry, it is believed that bakelite sheet will have a broader application prospect in the future.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……