The transformer skeleton is the main structural component of the transformer. It provides space for the copper wire in the transformer to wind and fixes the magnetic core in the transformer. The wire grooves in the skeleton provide a path for the transformer production winding, and the metal pins are connected to the PCB board to play a conductive role.

1.Fix the core: The skeleton fixes the core in the transformer through the core hole.

2.Provide winding space: The skeleton provides winding space for the copper wire, and the winding groove provides a path for production winding.

3.Conductive function: The metal pins in the skeleton are connected to the PCB board after soldering, which plays a conductive role when the transformer is working.

4.Fixed function: The retaining wall at the bottom of the skeleton fixes the transformer and the PCB board and provides a certain distance.

5.Direction and order determination: The convex points, concave points or chamfers in the skeleton can determine the direction or pin order of the transformer when it is used.

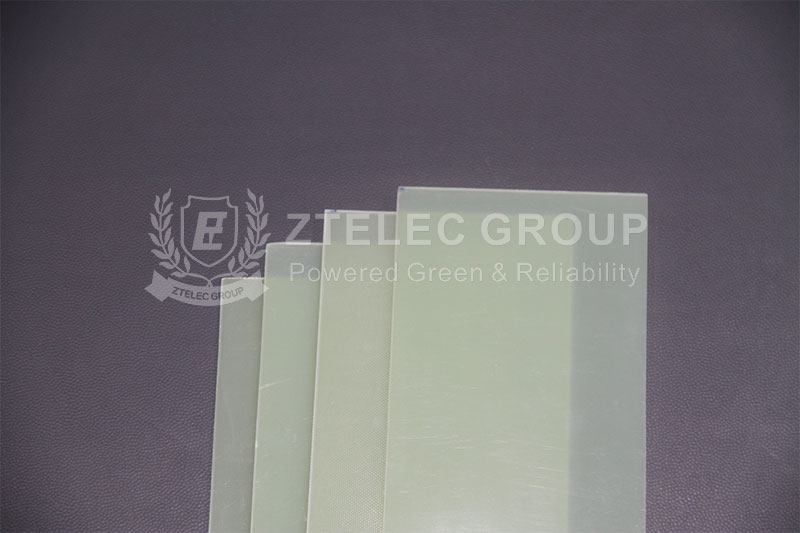

Flame resistance: FR-4 is a code for a flame resistant material grade, which means that the resin material can extinguish itself when burning. This feature makes FR-4 epoxy sheet extremely safe in electrical applications.

1.Electrical performance: FR-4 epoxy sheet has stable electrical insulation performance and can meet the requirements of electrical performance in transformers.

2.Mechanical strength: The material has high mechanical strength. So the material can withstand certain pressure and impact, and is not easy to break or deform.

3.Aging resistance and lifespan: FR-4 epoxy sheet is aging-resistant, has a long lifespan and is highly reliable. It is suitable for long-term electrical equipment.

4.High temperature resistance: In high temperature environments, FR-4 epoxy sheet can maintain stable physical and chemical properties and is not prone to deformation or aging. This feature enables it to perform well in environments with high temperature requirements.

The application of epoxy sheet FR-4 in transformer skeleton is mainly based on its unique material properties and the functional requirements of the transformer skeleton.

1.Making skeleton material: Because of the mechanical strength and electrical properties of FR-4 epoxy sheet, it is used as the main material of the transformer skeleton. This not only provides sufficient support, but also ensures that the skeleton has good insulation properties.

2.Design skeleton structure: According to the design requirements of the transformer, the plasticity of FR-4 epoxy sheet is used to design a skeleton structure that meets the winding requirements and core support. This includes determining the size, shape, wire slot layout, and location of metal pins of the skeleton.

3.Processing and assembly: Through cutting, stamping and other processing techniques, the epoxy sheet FR-4 is processed into the required skeleton shape. Then, the magnetic core, copper wire and other components are assembled on the skeleton to complete the production of the transformer.

Therefore, the epoxy sheet FR-4 is widely used in the production of transformer skeletons due to its unique material properties. Through reasonable design and processing, its advantages in electrical performance, mechanical strength, flame retardancy, etc. can be fully utilized to provide strong guarantees for the safe and stable operation of the transformer.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……