There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

Heat resistance rating: Class F(180℃)

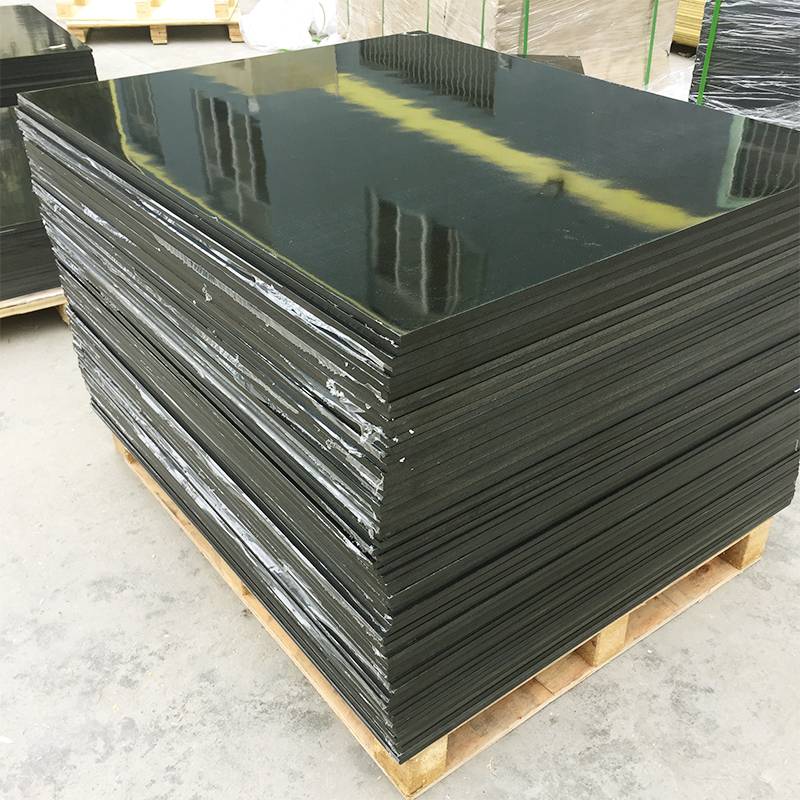

Thickness: 3-25mm

Size: 1020×1220 / 1160×1260 / 1220×2440

Color: Black or green, water green,white

Email:[email protected] Whatsapp:+8613137718313

Black FR4 anti-static fiberglass sheet is a specialized fiberglass material that incorporates anti-static agents during the production of FR4 sheets, enhancing their anti-static properties. The base material of this sheet consists of epoxy resin and glass fiber cloth.

The Anti-static fiberglass sheet precision is suitable for test board, electrical equipment insulation partition, insulation pad, transformer insulation board, electrical insulation parts, computer drilling pad mold fixture (PCB test stand).

1. Looks beautiful, smooth and no pit on surface

2. Good heat and moisture resistance, good electrical performance with dry and wet condition. Low water absorption is not easy to deformation.

3. High mechanical properties and good machinability.

Here is the video of the workshop of the Anti-static fiberglass sheet, you can see that the process progress of the Anti-static fiberglass sheet, include our workers and the machine for the production.

| Item | Unit | Value |

| Water absorption | % | <0.25 |

| Flexural strength | MPa | >350 |

| Surface resistivity (C-96/20/65) | MΩ | >105 |

| Volume resistivity(C-96/20/65) | MΩ·m | >104 |

| Dielectric lose factor (1MHz) | — | <0.03 |

| Heat resistance 220°C 20mm | — | No bubble |

| Flammability UL94 (1.6mm) | Class | V-0 |

| Solvent resistance | — | No change |

| Density | g/cm3 | 1.85-1.95 |

| Charpy impact strength | kJ/m2 | >45 |

| Size | mm | 1020×1220 / 1160×1260 / 1220×2440 |

| Note: Colors white, yellow, black, light green are available. | ||

Package & Storage: Wrapped with packaging film and packed in pallet; horizontally placed in dry and clean room at room temperature; keep it away from moisture and fire. The storage period is 12 months.

Here is the certificate of our insulation materials and factory, which can ensure the quality of the products which supply to our customers. In 2011, we obtained the certificates of ISO9001:2008 International Quality Management System, and ISO14001 organization environmental management system. Products including Power Distribution Cabinet, HV Switchgear, Transformer Substation, Complete Switchgear and power transformers (below 35kV) passed the tests from CNAS, IAC-MRA, AL, CMA and others international testing organizations.

If you need our products please write down any questions, we will reply as soon as possible.