There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

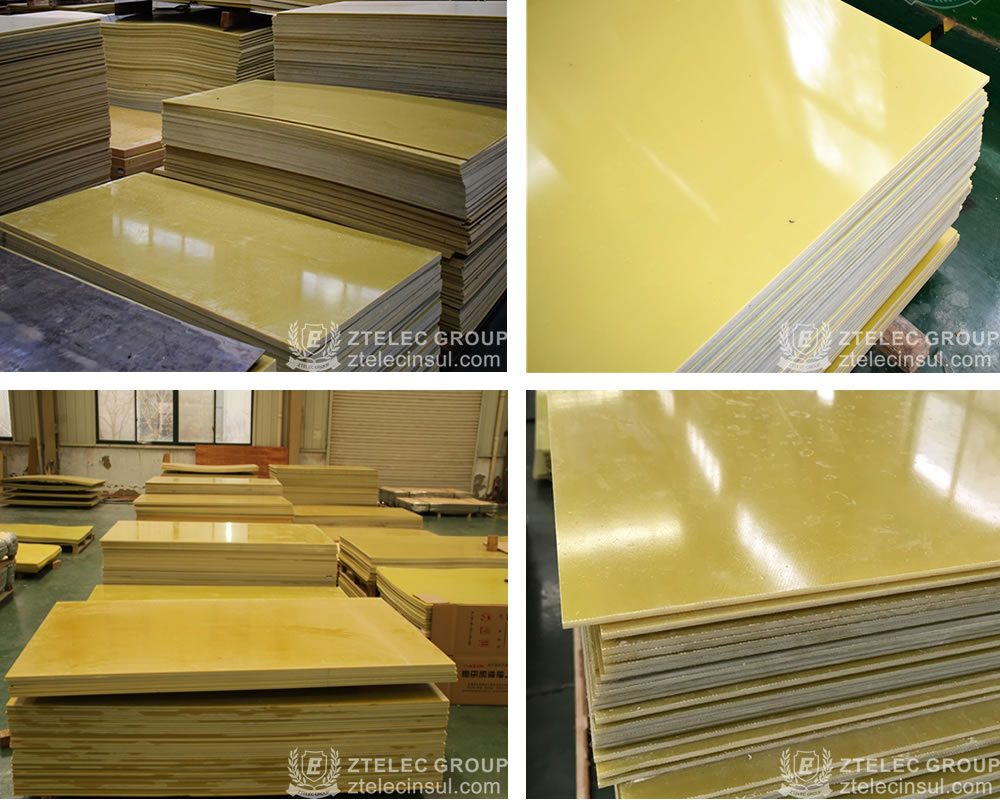

Color: Green/Water Green/White/Yellow/Black

Thickness: 0.1-100mm

Size:1020*1220 /1020*1020 /1220*2440 /1220*2040 (support customize)

Heat resistance grade: B grade

Email:[email protected] Whatsapp:+8613137718313

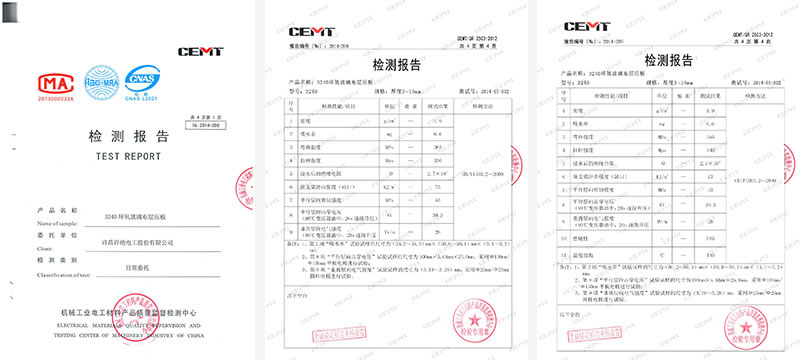

3240 epoxy fiberglass sheet is made of non alkali fiberglass cloth for electrical purposes impregnated with epoxy resin and phenolic resin under heat and hot pressing with excellent dielectric property and mechanical property, good heat and moisture resistance, strong mechanical processing property. It has high mechanical strength at medium temperature and stable dielectric performance at high humidity. The insulation class is B class.

Suitable for electrical, electronic, motor and mechanical industries and other industries. It can be processed into various insulation accessories and insulation structural parts of equipments, and can be used in humid environment and transformer oil.

Thickness: 0.5~50mm under normal, and thick board with 50~150mm is available as required.The density of the sheet is approximately 2.1 g/cm³.

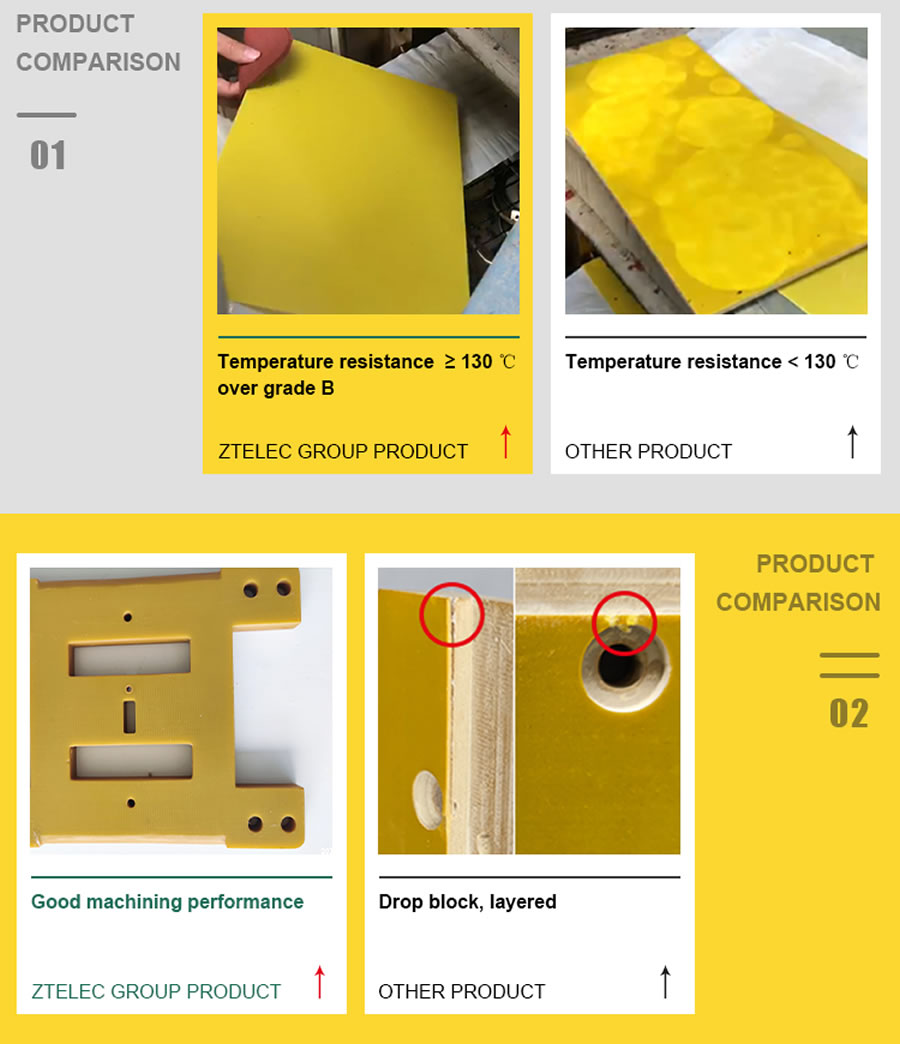

3240 epoxy fiberglass sheet, produced by ZTelec Group using non alkali fiberglass cloth for electrical purposes, epoxy resin and phenolic resin as raw materials, can be mass-produced with advanced production equipment and automatic production line. This product has the advantages of reliable quality, smooth surface, neat cutting edge, uniform color and small thickness tolerance with strict manufacturing technology. The mechanical and electrical properties of products are superior to the similar one of other companies. Its quality is recognized by domestic and foreign large enterprises such as Lens Technology in China and Schneider Electric and sold overseas such as European and American areas.

Compared with other products, our products are of good quality and more cost-effective

| Number | Item | Unit | Value |

| 1 | Density | g/cm3 | 2.1 |

| 2 | Water Absorption | mg | 22 |

| 3 | vertical layer bending strength (normal state) 150℃13℃ | MPa | ≥340 |

| Vertical layer compression strength | |||

| Parellel layer cutting strength | ≥30 | ||

| 4 | ParellelImpact Strength at Parallel Lamination(Simple Supported Beam) | KJ/m2 | ≥33 |

| 5 | Dielectric Strength at Perpendicular Lamination(Transformer Oil at 90℃) | KV/mm | ≥10.2 |

| 6 | Breakdown Voltage at Parallel Lamination | KV | ≥35 |

| (Transformer Oil at 90℃) | |||

| 7 | Dielectric Constant(50Hz) | – | ≤5.5 |

| 8 | Dielectric Loss Factor(50Hz) | – | ≤0.04 |

| 9 | Insulation Resistance after Immersion | Ω | ≥5.0×104 |

| 10 | Thermal Index | ℃ | 130 |

| 11 | Tracking Resistance Index(PTI) | – | ≥200 |

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 60 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first.

If you are looking for 3240 epoxy sheet, please contact us,we will provide you with product catalog and quotation, and can also mail you free samples for your testing.

Welcome to visit our factory for guidance.

If you need our products please write down any questions, we will reply as soon as possible.